Vibrations – damaged power cord identification

This article is for those interested in predictive maintenance, who have already seen an infinite number of practical cases of identifying bearing faults, with vibrations.

Shoulder fish:

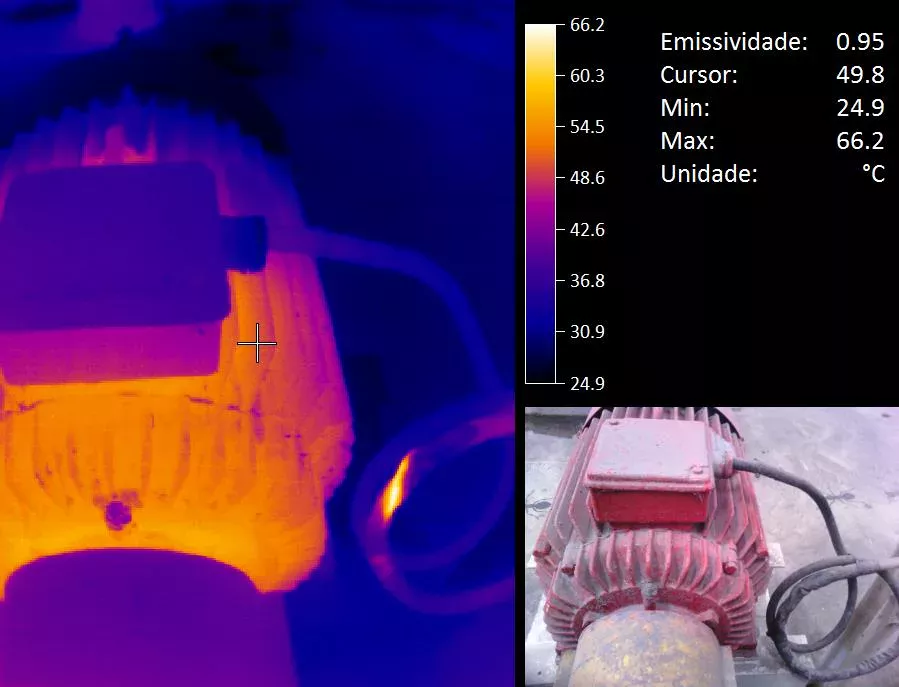

During a routine machine inspection, with the ADASH VA5 Pro, in an industrial unit that is a DMC client, the technician used the thermography camera and identified a hot spot, on an electric motor power cable.

Figure – Thermography and photography, taken en route, with the ADASH VA5 Pro.

This hot spot corresponded to cable damage.

What allowed the identification of this fault?

- The use of a vibration data collector with the possibility of performing thermography, like the ADASH VA5 Pro;

- The coach’s desire to go further, the application of predictive maintenance techniques.

It is known that electrical inspection for hot spot detection with thermography, It is usually located on the electrical panels, transformers and substations and does not usually go to motors. Who goes to the engines most often?, are the vibration technicians.

What this case shows?

- That fault detection capabilities still exist, to explore, in portable equipment,

- That a predictive maintenance technician, with the appropriate tools, can go further in fault detection;

- That this ability is also dependent on the technician's willingness to get out of his routine.

Congratulations to DMC technicians who are exploring new opportunities to identify faults!

I know the name of this article is misleading., but it was on purpose; what matters is that this is a good example, and that goes beyond what is usual…