Vibrations and toothed couplings

Vibrations and toothed couplings

This article talks about vibrations and toothed couplings. It refers in particular to the influence of a toothed coupling on the vibratory behavior of a machine when a misalignment.

Misalignment – the influence on coupling vibrations

The type of coupling installed on a shaft line, defines what a misalignment outside of tolerances is, in the coupling.

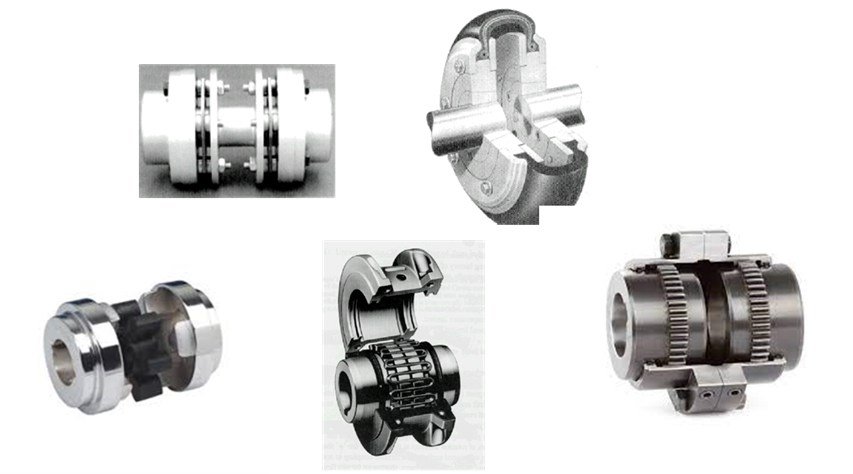

Figure - Various types of coupling

A coupling is a mechanical component that connects two shafts, to transmit power. Couplings introduce some flexibility into the mechanical transmission, providing misalignment tolerance.

As a result, this coupling flexibility can reduce bearing wear, equipment vibration and other mechanical problems due to misalignment.

Vibrations and toothed couplings – Coupling Functions

The main functions of couplings are:

- power transmission;

- Absorption of misalignment;

- Vibration absorption for component protection;

- Prevent heat transfer to the driven side.

It takes considerable time to align a motor shaft with a drive shaft with high accuracy.. If the shafts of two shafts are misaligned, extra force is repeatedly applied to the rotating parts, as they spin, what causes vibration and noise and, often, causes the appearance of fatigue cracks, that can cause the veins to break.

Besides that, although the same parts are used to manufacture units, there may be errors such as machining accuracy, so it is very difficult to assemble each unit accurately, because the dimensions are different from each other. Therefore, a coupling must be used to absorb assembly errors.

The coupling has the role of transmitting power dynamically and precisely, even if there is a misalignment (eccentricity/ angle, axial displacement, etc.) between the two shafts.

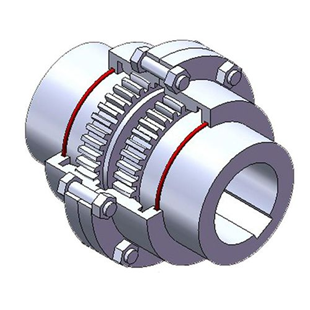

the toothed coupling

You toothed couplings work like a gear. That is, transmit the torque through hubs with teeth.

Due to the gear, These couplings are indicated for the large binary transmission and accommodate misalignments in all directions, axial, parallel and angular.

They are used when there are high speeds and high torques., with a long service life.

according to your application, gear coupling needs mechanical lubrication periodic. if done correctly, the service life of this coupling lasts for years.

Vibrations and toothed couplings – Misalignment absorption by a toothed coupling

The use of a stroboscope for misalignment diagnosis has the advantage of not requiring specific knowledge of vibrations and of being easily interpreted., The use of a stroboscope for misalignment diagnosis has the advantage of not requiring specific knowledge of vibrations and of being easily interpreted..

Figure – The use of a stroboscope for misalignment diagnosis has the advantage of not requiring specific knowledge of vibrations and of being easily interpreted..

actually, this is what happens when the machine is immobilized. However, when the machine is running, the power transmitted by the coupling together with the friction force will drastically reduce this relative mobility and, from a certain value of transmitted power, the set will be completely blocked. Therefore, there is a misalignment, this can be completely absorbed by the coupling with the machine running at a reduced load, and no longer be, when the machine is fully loaded. Depending on the load conditions of the machine, this can present, or not, vibration symptoms of misalignment.

The variation of load conditions of a machine with this type of coupling, so this is a test to perform, to determine if misalignment exists in the coupling.

Vibrations and toothed couplings – Example – Vibrating behavior of a misaligned fan, with toothed coupling, during the stop

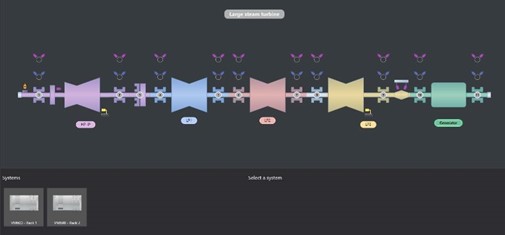

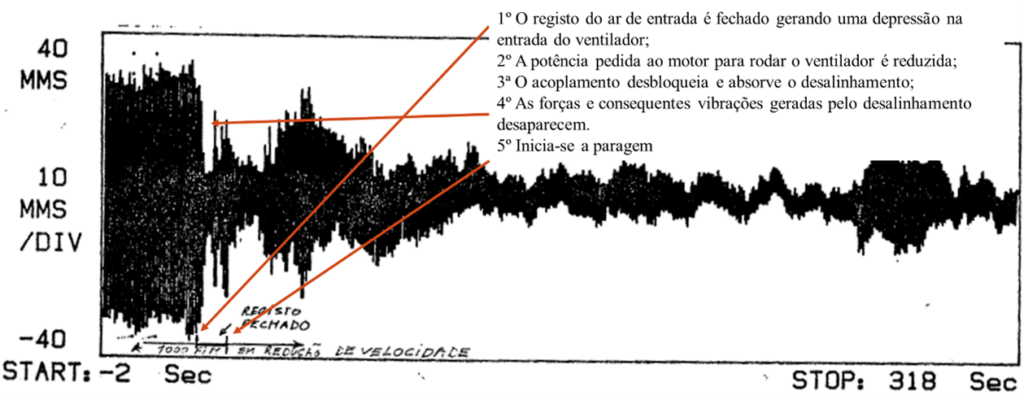

In the following figure, you can see the long duration waveform of a fan, with toothed coupling, during your stop.

Figure – Long duration waveform of a fan, with toothed coupling, during your stop

Note the phenomena that led to the start of the stop:

- The inlet air damper is closed generating a depression at the fan inlet;

- The power required from the motor to run the fan is reduced;

- Toothed coupling unlocks and absorbs misalignment;

- The forces and consequent vibrations generated by misalignment disappear.

- The stop starts

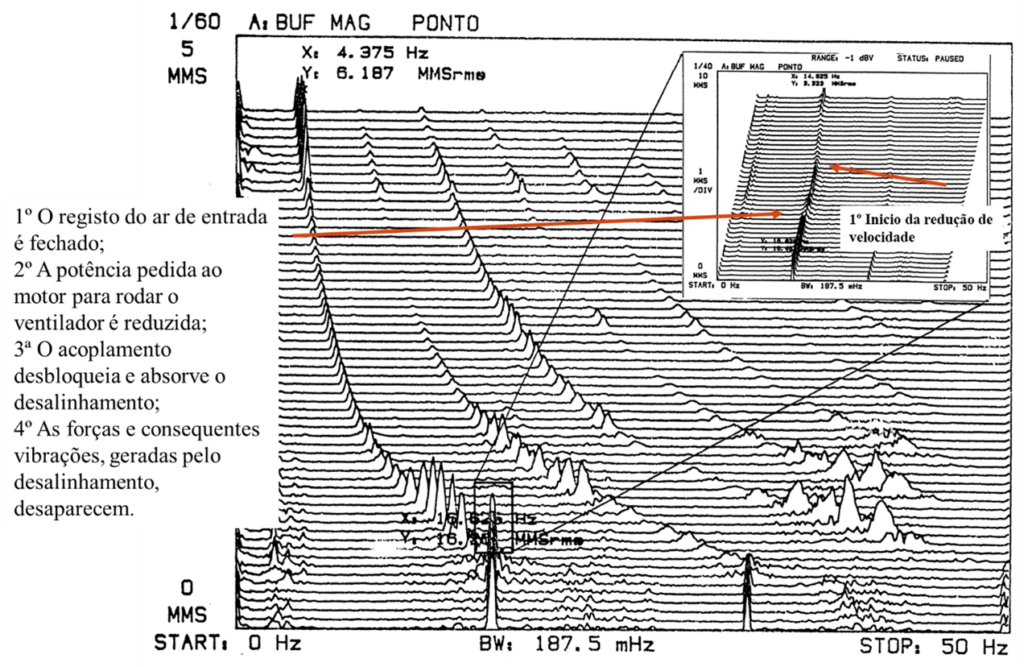

Below you can see a spectral map of this same stop.

Figure – Spectral map of fan vibrations, with toothed coupling, during your stop

Note the large reduction in the vibration level of the component to 1 x rpm, as soon as the power transmitted by the coupling is reduced and absorbs the misalignment.

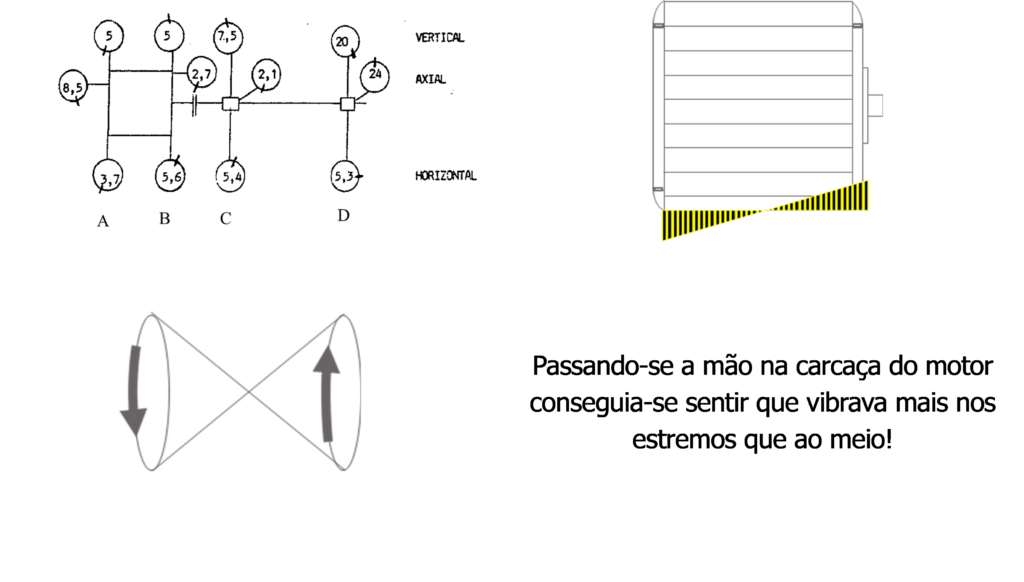

Example – Phase analysis of motor/fan joined by a toothed coupling, misaligned

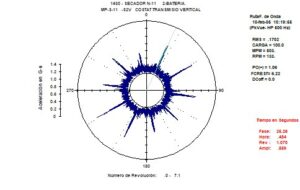

The following figure shows the amplitude (inside each circle) and the phase (marked by a cross in each circle) from component to rotational speed, measures in three directions, in all bearings, on a machine with a coupling misalignment.

Figure - Amplitude and phase of the vibration a 1 X RPM on a fan with a coupling misalignment.

Note the following aspects:

- phase difference of 180 degrees in the measurements on the motor in the vertical direction

- I'm going horizontal

- Strictly equal phase in measurements in the same direction on the bearings on both sides of the coupling due to the coupling being locked.

- Running your hand over the engine housing, you could feel that it vibrated more at the ends of the engine than in the middle.!

In these circumstances it can be considered that the coupling, toothed type, was absolutely blocked and caused the two closest bearings to vibrate in block. Simultaneously, it forced the motor to an oscillatory movement..

Thus, it is normally considered that phase differences of 0 (in toothed couplings, when blocked) or 180 degrees are symptoms of misalignment. the difference of 0 degrees means the coupling is locked.

Example – Load variation on misaligned alternator with toothed coupling

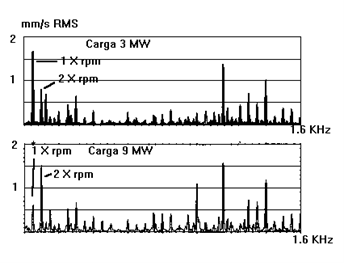

In the figure below you can see two frequency spectra measured at the same measuring point, in a bearing of a generator set reducer, in the axial direction, together with a toothed coupling.

Spectra were measured a few minutes apart.:

- one with the alternator with 3 MW

- the other with 9 MW.

Figure – Spectra measured in a turbogenerator group, on the gear unit's bearing next to a toothed coupling, in the axial direction, with the alternator with the load of 3 MW (top specter) e 9 MW (low spectrum).

Note the relative size of the components at one and two times the speed of rotation in the top and bottom spectrums.. In the upper spectrum, there are no symptoms of misalignment, while in the lower spectrum this is already noticeable..

The coupling when transmitting 3 MW of power was flexible and absorbed existing misalignment; the same did not occur when transmitting 9 MW.

In toothed couplings, when the condition of the teeth degrades, a vibration begins to appear at the gearing frequency. (number of coupling teeth times rotation speed). Therefore, in this type of coupling, it is important to monitor this frequency.