Thermography in vibration routines - Practical example

Thermography in vibration routines - Practical example - “now”

-

Introduction Thermography in vibration routines - Practical example - “now”

In this practical case, will be described as through the integration of thermographya baby vibration routines, this detected another malfunction, with a high potential to stop production. This took place without further workload for the inspector.

This malfunction was, potentially, strongly penalizing the economic results of the factory.

-

How to combine thermography into vibration routines?

Integrated computer programs for vibration inspection and thermography make it much more practical for a technician to have the necessary capacity to perform thermography and vibration routines.

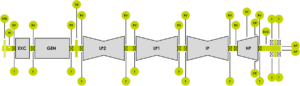

In the integrated computer program for vibrations and thermography, creating equipment and measuring points, a thermography point is created on each machine.

When creating routes, equipment inspection these thermography inspections are automatically included.

This inspection is only carried out if the inspector considers it appropriate.

-

O vibration analyzer as a platform for integrating predictive maintenance technologies

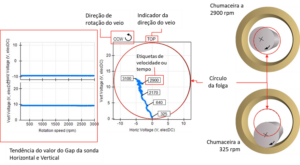

Thus, the two technologies come together on a single platform through the integration of image and image analysis functionality in a portable vibration device.

|

|

In this equipment, when you want to use, the thermography chamber is connected to a USB plug on the top of the equipment, as you can see in the photos.

-

Practical case - the machine next to it has already been looked at

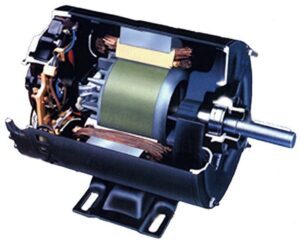

During a vibration measurement routine, a question arose. So the technician, how had the thermography equipment, decided to do a thermography to the equipment where he was measuring vibrations. Did not find anything unusual in the equipment in question.

However, since the camera was on, looked around, for other machines.

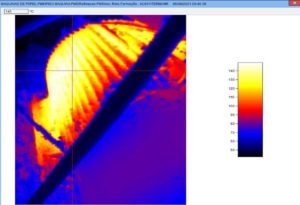

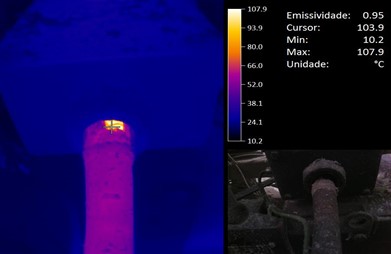

The following figure shows what you identified. An engine power cable on the side, a 108ºC.

Those responsible are alerted, the engine box was opened for visual inspection.

The engine box was very dirty and the cable from one of the phases was severely degraded. So there was a risk of generating a fire.

-

Conclusion

Thus, no more workload, a further malfunction was detected with a high potential to generate a production stop strongly penalizing the economic results of the factory.

This was made possible by the inspection technician's commitment to use all the technologies at his disposal and these are available.