A DMC, with its on-site balancing service, it provides maintenance managers with the ability to balance the shafts of their machines without having to go through a complicated process., expensive and time-consuming disassembly of the shaft to be balanced on a bench.

The imbalance of the rotors is a problem that becomes all the more important the greater the power and speed of the machines.

- It is one of the most frequent causes of vibration in rotating equipment.

- The balancing becomes necessary to prevent the appearance of cracks, avoid excessive loads on the bearings and extend the life of equipment.

The balancing is the operation through which improves the mass distribution of a rotor so that in their operation do not appear excessive centrifugal forces.

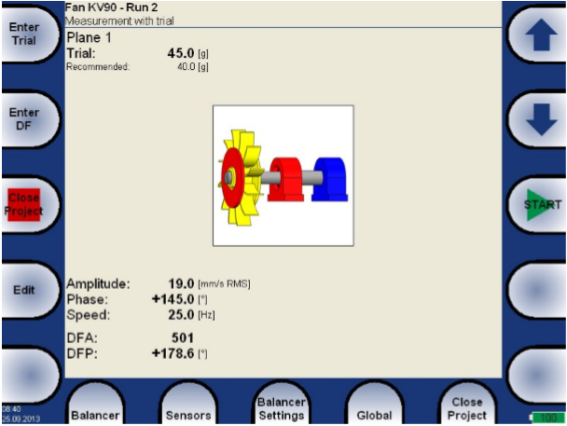

The balancing in place in practice

- General rule, for any machine, You can define a level of vibrations, considered acceptable.

- This level is obtained from measurements made when the machine is in good working condition or on other similar machines.

- The vibrations generated by imbalances depend not only on the value of the imbalance of the machine but also the mobility.

- With a portable on-site balancing measure the vibration amplitude and angle that can be used to calculate the position where to place the correct mass.