The vibration analysis service provided by the DMC identifies the cause of an abnormal vibration behavior in a machine.

The intervention of vibration analysis can take place in different circumstances:

- Trend Monitoring

- Checking the condition

- fault diagnosis and problems

The DMC is a certification body vibration analysts accredited by VIBRATION INSTITUTE

control condition

Table 1- Comparison of Condition Control methods of the Troubleshooting and Problem

| Trend Monitoring | Checking the condition | fault diagnosis and problems | |

| Height measures | Readings taken at regular intervals with the machine in service | Readings once with the machine in service | When the problem occurs, or after the occurrence of the fault |

| Qualitative measures | Qualified operators who are near the machine may make a subjective trend | Typical activity when a technician checks a service machine | When a machine for inspection of components may indicate the cause of the problem |

| Quantitative measures | Registration and interpretation of the results of regular measurements gives a warning period compared to machine problems | The numerical values allow comparison with standards or other similar machines knowing the condition of the equipment | Inspection results can be analyzed in considerable detail by providing information on the possible causes of the problem |

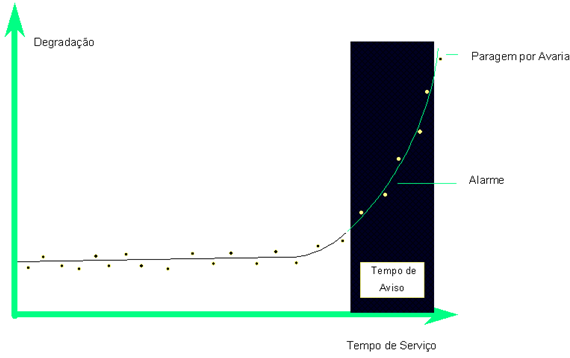

- Based on the measured values, prepares a tendency for determining when the degradation of a machine exceeds a critical state.

- The principles involved are illustrated in the following figure, showing the means by which the monitoring of the trend may give a warning time before the decay reaches a level at which the machine has to be put out of service.

- The warning time before failure occurs, It is one of the main advantages of using trend-following rather than alarms or security systems to stop the machine automatically.

- Vibration analysis, to make a diagnosis, It takes place when it identifies abnormal behavior.