A DMC, with its shaft alignment service, it makes available to maintenance managers the ability to align the shafts of their machines with precision technology to align the shafts.

- With guaranteed results

- Without having to carry out a complicated, expensive and time consuming training of staff;

- Without investment in precision alignment equipment;

Misalignment shafts

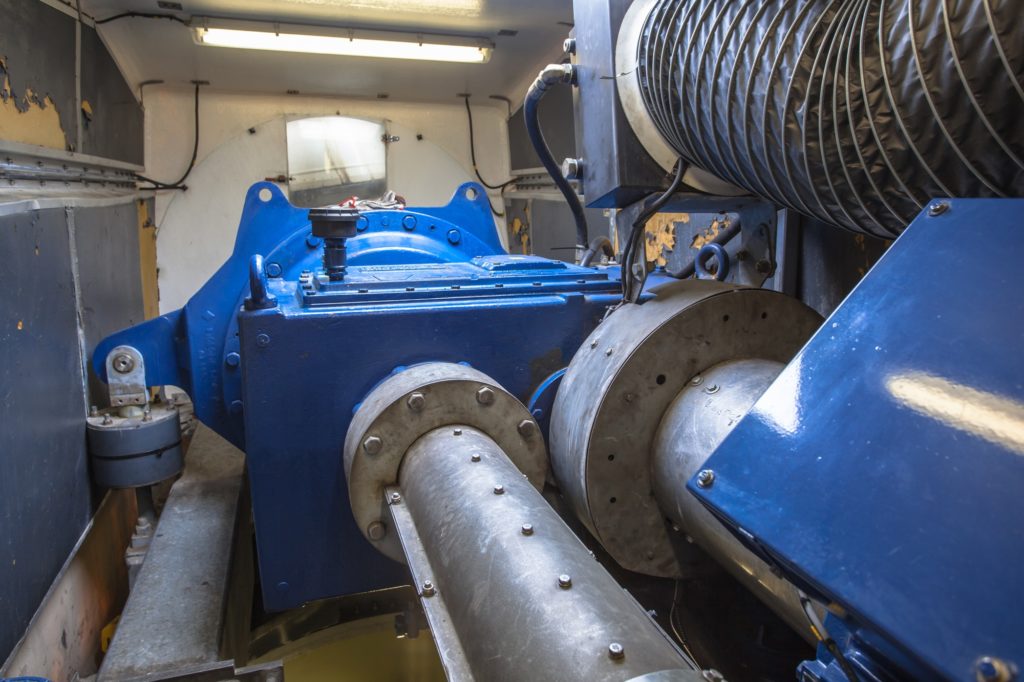

The shaft misalignment is a mechanical defect which is defined as:

- The lack of spatial coincidence of the geometric rotation shafts of two drive shafts coupled.

- The concept of misalignment is also definable for other types of transmission (pulleys, cardan, etc.) as the lack of complanariedade of geometric shafts.

- Finally, the same concept is applicable to characterize the relative position of a shaft relative to its supporting elements (bearings or bearings).

According to studies published in the Journal TAPPI in December 1990, the inclusion of a compliance program precision shafts within the maintenance plan may involve:

- An increase in bearing life up 8 times

- Absolute reduction in maintenance costs of up to 7%

- An increase in the availability of up to machines 12%

- A reduction in downtime due to misalignment of up to 50%

- Savings of 5% energy consumption