The Sayano Shushenskaya dam disaster

The Sayano Shushenskaya dam disaster

The Sayano Shushenskaya dam disaster occurred in 17 August 2009, causing the death of 75 people.

Poor maintenance and design and lack of emergency training, caused a catastrophic accident at one of the largest hydroelectric power plants in the world.

A 16 August 2009 unusual load demands were made on the plant ,. few hours later, one of the plant's generators exploded and in seconds thousands of liters of water flooded the generator set room.

Near 75 people were drowned or lost, the siberian network fell 10% of your capacity, oil was also spilled into the Yensei River, generators and transformers being destroyed and concrete structures severely damaged.

The problem started at the nearby Bratskaya hydroelectric power station. ( the 1,400MW) during the night before the accident. A fire caused its network regulation function to be transferred to Sayano Shushenkaya. The turbo-generators that received the load, particularly the unit 2, it was old and poorly maintained.

The generally accepted opinion, is that the water hammer in the penstock caused this unit to fail and literally explode, throw the generator and turbine many meters into the air, thus allowing water from the reservoir to flood the generator set room.

When fully operational, the Sayano Shushenkaya hydropower plant comprised ten units of 640MW, producing 24,000GWh per year, with a capacity factor of 42 Percent. The units were fed from a reservoir about 220m deep on average, created by a dam 245m high and 1km long on the Yenesi River. It was one of four hydroelectric plants with a combined capacity of 20,700MW, that provided, together, more than two-thirds of East Siberia's electricity demand. It was the sixth largest hydroelectric power plant in the world and the largest in Russia..

Description of a survivor

…I was upstairs when I heard a growing noise, then I saw the corrugated turbine cover rise and stand. Then I saw the rotor rising underneath it; was spinning. I couldn't believe my eyes. Got up about three meters. Rocks and pieces of metal flew; we started to dodge them. then, the corrugated roof was almost level with the roof, and the roof itself had been destroyed. I did a mental calculation: the water is rising, 380 cubic meters per second, therefore, I picked up on my heels and ran to the turbine 10. I thought I wasn't going to make it. climbed higher, I stopped, I looked down, and saw everything being destroyed, water coming in, people trying to swim…. I thought: someone must close the gates urgently to stop the water, manually. manually, because there was no energy, and none of the protection systems had worked…

State of the generator room before and after the accident

The generator room before and after the accident. The Turbine That Failed, is visible in the foreground.

The Sayano dam disaster Shushenskaya – The accident

The accident occurred at 8:13 . there was a bang ; the turbine cover was ejected and the rotor of 920 tons later shot out of your seat. As a result, the engine room and rooms below its level were flooded. At the same time, an alarm was received on the main control panel of the control panel, and energy production dropped to zero, resulting in a local blackout.

The steel gates for the penstocks for water inlet to the turbines, weighing 150 tons, were manually closed by opening the valves with hydraulic jacks. The operation took 25 minutes.

The Sayano dam disaster Shushenskaya –Accident Investigation Results

A 4 October 2009, the official report on the accident was published.

The names of the victims and those responsible for the accident were presented in the report., as well as other data, including a historical and technical review of the plant and plans for its future.

maintenance problems

The report states that the accident was mainly caused by turbine vibrations that caused fatigue damage to the turbine mountings 2, including turbine cover. It was also found that at the time of the accident, at least six nuts were missing from the screws that secured the turbine cover.. after the accident, were investigated 49 recovered screws, of which 41 had fatigue cracks. In 8 screws, the area damaged by fatigue exceeded 90% of the total cross-sectional area.

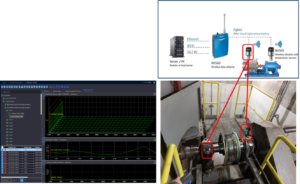

Although a new vibration protection system in the unit 2, this one was not working. The weekly vibration readings from April to 11 August showed that in the week before the accident, vertical displacements had reached 1,500µm, more of 700 percent above the maximum permissible 200µm. at the point of failure, era 525 percent higher. three months before, the level was 250µm. If the protection was working, the machine would have automatically stopped at this point or shortly thereafter.

operation problems

According to this report, a 17 August 2009 at 01:20, there was a fire at the hydroelectric power station in Bratsk which broke both the communications and the automatic conduction systems of other power stations in the region, incluindo Sayano-Shushenskaya. The situation was restored to 17 August 2009 at 15:03. At 08:12, the output power of the turbine 2 was reduced by the turbine regulator and it entered energy band II not recommended.

the catastrophic failure

shortly after this, the bolts that held the turbine cover in place broke, and under water pressure of approx. 20 bar, the turbine with its cover, rotor, and upper parts began to move upwards, destroying the engine room installations. At the same time, pressurized water flooded rooms and damaged facilities.

The automatic closing system of the water inlet gates of the pipes did not work.

The loss of life could have been less if an emergency protocol had been established, but there had never been any evacuation drills, and generator emergency support has been activated. The lack of backup power also contributed to the problem.; the center was in total darkness.

The Sayano dam disaster Shushenskaya –Background

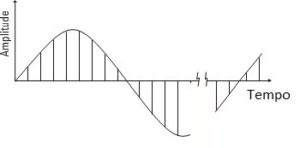

Turbines of the type used have a very narrow working range in high-efficiency regimes.. If this band is exceeded, the turbines start to vibrate, caused by pulsating water flow and water hammer. These vibrations and shocks cause the turbines to deteriorate over time..

Turbine 2 had had problems for a long time before the accident 2009. Over time, numerous problems with seals have arisen, turbine shaft vibrations and bearings. Found on turbine wheel and repaired, cavities with up to 12 millimeters deep and cracks up to 130 millimeters long. Many other defects were found in the group's bearings and subsequently repaired..

during repairs, the turbine blades were welded, because after a long period of operation, the fissures and cavities had once more appeared. Turbine rotor was not properly rebalanced after these repairs, after which the vibrations had increased, near 150 microns to main bearing, during full turbine load. Although this did not exceed the specifications, increased vibrations were unacceptable for long-term use. The high levels of vibration compared to other turbines were visible for the turbine as well. 2, before repair. Vibrations exceeded the allowable specification in early July and continued to increase.

Operating characteristics

The electrical network fed four large aluminum foundries, whose loads fluctuate a lot. Normally, Bratskaya provided grid regulation and Sayano Shushenkaya the baseload.

The long-term goal of the factory owners, RusHydro, was to supply electricity to more than the smelters and interconnect with nearby grids, what made regulation important to the network. But although Bratskaya was able to accomplish this, Sayano was not. Load fluctuations were severe and rapid, a feature of aluminum foundries. incipient failures, both electrical and mechanical – and there were many in Sayano – soon become active. If the machines had continued to deliver the base load, the accident would not have happened at that particular time, but it was bound to happen sooner or later.

None of Sayano Shushenkaya's machines were suitable for extended adjustment service but, of the ten machines, the unity 2 was selected as the best available and was

decided to use it for frequency control. One unit was on standby, another one was under maintenance, and the remainder continued to provide baseload. The unity 2 was near the end of its recommended shelf life of 30 years – in August 2009 it was already working 29 years and nine months.

However, had been recently maintained and was thought to be the most reliable unit, although it turns out that this maintenance was grossly inadequate.

Operational demands were heavy. US 13 minutes before the accident, the unit had fluctuated from 170MW to 600MW six times, against a rated power of 640MW. Every time the load changed, the machine had to go through the so-called 'unstable zone’ when vibrations were higher than normal. Besides that, the height of the reservoir was 212m, as opposed to the design level of 197m. This provided the optimal conditions for mechanical failures.. Turbine often rotated in an unstable zone, with the added strain of decelerating and accelerating under a height 15m above design level.

The days before the accident

on the night of 16-17 of August, the vibration level has increased substantially, and there were several attempts to stop the turbine. During 16 from August until 20:30, the turbine load 2 was from 600 MW, and then reduced to 100-200 MW. A 17 August 2009 at 03:00, the load was again increased to 600 MW; at 03:30, the load has been reduced to 200 MW; and the 03:45, was again increased to 600 MW. During this time, the vibration level was very high. When trying to turn it off, the rotor inside the turbine was pushed up, which in turn created pressure pushing up on the turbine cover, which was held in place by 80 screws, each with 8 cm in diameter.

Turbine 2 was started to 16 August 2009 at 23:14, local time. At 23:44 was running on a full charge of 600 MW. During the night, their load varied between 10 e 610 MW. At the time of the accident, which was at 08:13, your load was 475 MW and water consumption was 256 m3/s. The bearing vibration was 840 microns, which far exceeded the values of the other turbines, more than four times.

The turbine often operated in a regime that is accompanied by pressure pulsations and water hammers..