MPM- A global approach to the maintenance function

MPM- A global approach to the maintenance function in a metanional environment … from asset management to reliability

1 – MPM – PREAMBLE

The machine that inexplicably, for everyone involved, starts working properly soon after a specialist arrives. This after its operators/users had done everything they could and it was within their power, with nothing having resulted; countless hours of work, disproportionate efforts, multiple actions than in the past, and in other circumstances, gave the intended results and, However, no present case, nothing…

How to explain this situation?

The machine exhibiting worrying behavior, at least in the eyes of those responsible, it's not for continuing, in an inexplicable way, to function properly, that stops having a problem!

What kind of problem?

The machine that worked for years without problems and that when its former operator is absent, it starts to present numerous problems and breakdowns.

what is happening?

De facto, these and other similar situations, are part of the daily life of the maintenance professional, what, However, well you can look for references and approaches to solving this type of problems, in specialized magazines, national and international conferences and on the internet you can't find anything.

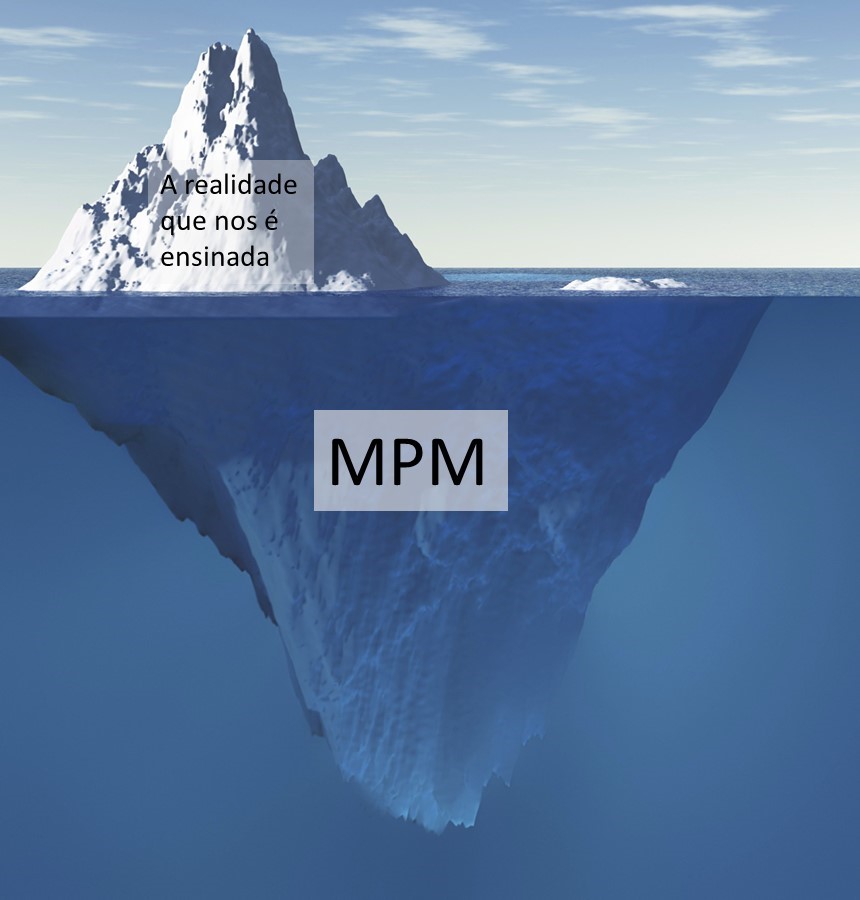

It gives the idea that there is a part of reality that, such is the lower part of an iceberg, for being out of our sight, is ignored by us. On purpose or perhaps due to the profoundly technical training of specialists in this area, unexplained facts, that can even be considered normal in our professional life, are immediately forgotten and do not deserve a minute's attention from us., for deeper reflection.

However, at a time when among the explicit objectives of any professional are zero breakdowns, (if this is truly our goal),the optimization of asset management, o do RCM, o do TPM, o do TQ, ERP, PPP, PBC, VCM, TDM, PDM, PPM, PSD, IA, etc. , nothing can be put aside, as strange as it seems, under penalty of, the game, commit to its fulfillment.

That's how, with an unshakable will to overcome all the obstacles that stand in the way of reaching impossible goals, we have to launch into the search for the explanation of what is not yet explained, in optimizing what is not optimized, of knowing that is not known. Nothing can come between us and the truly global approach to maintenance that we, once for all, assure us, in an automatic way, achieve that Holy Grail of modern management theories which is the last Optimization of Asset Management.

Here it is at last within our reach – MPM !

2 - INTRODUCTION

The tendency for equipment to have more and more built-in intelligence is a reality of our days. The logical consequence is that this intelligence will be an increasingly significant reality., generating, in turn, of important problems. The fact that equipment works in an increasingly autonomous way implies that they have an increasing decision-making capacity. The works of a notable Portuguese1 which show that at the basis of any decision process is emotion. IS, therefore, logical to infer that there are emotions and affections in machines. This reality felt by many, but rejected as a rational explanation, finally has a scientific basis!

So we have the answers to the questions asked in the preamble:

- Machines have memory

- Machines have an affective relationship

- Machines recognize experts

- Machines have psychological problems

- E, to complete, do we exist?

3 – THE MEMORY OF THE MACHINES

For those who don't believe that machines have the ability to remember the past, take the following case as an example:

| “The important lesson is that the carrier does not “he forgot” the harsh treatment and the expected shelf life has been greatly reduced. …. Explain that a machine “remember” can sometimes speed up response times to abnormal machine operator operations. However, tell the operator “that the machine remembered” it can also generate some very strange looks from those who might question their sanity.”2 |

obvious conclusion: Machines have the ability to remember...

4 – THE AFFECTIVE RELATIONS OF THE MACHINES

The machines, de facto, create affective relationships with those who are close to them.

An example of refusal to see reality and non-recognition of the existence of an affective connection between the machine and its operator can be seen below.3.

| Don't underestimate the experience A true story highlights the importance of lubrication to machine life. There are about 25 years, a chemical plant had a compressor house that contained several ammonia reciprocating compressors. The machines rarely required maintenance and were essentially ignored by maintenance and management.. However, a chief operator, who was about to retire, did checks, including cylinder lubricator maintenance, on all shifts I worked, and had been doing this for about 30 years. He told his supervisor that he would be happy to train a younger operator in what he did.. However, this plant has changed its management philosophy in recent years and is now placing young engineers in operational supervisor positions as a training assignment on their way to plant management. This young engineer lacked the practical field experience to understand the implications of what the chief operator was doing and, in an attempt to reduce the workforce, has not assigned anyone to this training opportunity. Two months after the boss makeover, one of the compressors suffered a catastrophic cylinder/frame failure. As the machines were originally built in the 1990s 1930, parts were not available and the compressor was scrapped. An investigation of the failure later revealed that the cylinder lubricators had run out of oil weeks before the failure., as no one knew they had to be replenished manually, weekly. This was a task the former chief operator had been doing for 30 years. |

5 – MACHINES RECOGNIZE EXPERTS

my experience

For many years I provided training and technical assistance in the use of measuring equipment and software. I was also a colleague of many technicians with the same functions.

At the end of all these years, I became very skeptical of the claim, spoken by a user, that a piece of equipment or software does not work. De facto, my experience tells me that, when i get in touch with him, there is a high probability that it will work...

This even after its operators/users have done everything they could and it was within their power, with nothing having resulted; countless hours of work, disproportionate efforts, multiple actions than in the past, and in other circumstances, gave the intended results and, However, no present case, didn't result in anything.

It could be hypothesized that the specialist had done something different. However, this is of low probability in view of the efforts previously made by users. The most likely explanation and, de facto, machines recognize feel, the presence of the expert.

The explanation, simpler, of dullness and readily denied by normal users and has to be set aside, obviously…

6 – MACHINES HAVE PSYCHOLOGICAL PROBLEMS

I think it's part of any coach's experience, be faced with performing maintenance tasks, whose execution, can only be explained on the basis of psychology.

For example, I know people who, to the great satisfaction of its suppliers, change the oil in your car's engine, of 5000 in 5000 km, this despite the manufacturer recommending changing 15000 in 15000, or from 30000 in 30000.

Because? This is an obvious case of a psychological problem in the vehicle..

For a more informed person, the vehicle apparently, doesn't present any problem. However, for its owner, this exists and has to be dealt with.

We are facing a machine with a psychological problem, that will justify the investment in the necessary resources for it to disappear.

And it's not a unique case. For example, interventions carried out under the so-called “cagaço coefficient”, usually fall in this range.

7 – MPM – DO WE EXIST?

A few years ago an acquaintance of mine, maintenance professional, he wrote:

| The biggest lie of maintenance professionals When this goal is achieved, those who worked tirelessly to achieve it will be fired immediately as they are no longer needed from an asset management optimization perspective.. Whoever hits him will be a victim of his creation, in a remarkable similarity with Dr.. Frankenstein; what irony! No maintenance professional who lives on what they earn, he will no longer keep the last residual failure of the equipment under his charge as a precious asset to guarantee the maintenance of his children!! After countless years of continuous implementation of proactive tasks, and to our astonishment, RCM's dream, that on a first impression, it seemed to us to be just the last trick of the consultants with little work, not being able to reach, it's right there at our fingertips. It is then that, on the edge of the cliff, on the verge of committing this final madness, to correct that last precious potential flaw final guarantee of our livelihood, The vision of this adorable little child comes to mind., that every day awaits us in our house, with a smile, at the end of another busy day, and who trusts us, blindly, to guarantee you protection and sustenance. Ò Cruel Dilemma – Child Support or Optimizing Asset Management? |

elsewhere4), John S. Mitchell, referred:

| the missing element – clear financial justification No article by this author would be complete without the usual editorial discourse on financial justifications. Despite over fifty years of success and demonstrated benefits, condition assessment programs are not yet fully accepted within an industrial operating culture as an ongoing and essential business activity. Many tremendously successful programs are scaled down or shut down entirely as a “cost saving” measure because breakdowns are scarce.. Many new managers are said to believe that fixing equipment when it breaks down is the least expensive maintenance method.. “Why do people have fun collecting and analyzing condition measurements when they could be doing real work repairing things that need attention?!” Many technicians, successfully in this area, are equally guilty. Analyzes and details, such as determining that a bearing is failing due to a defect in the outer race, are of much more interest than demonstrating the value they contribute to their companies. For example, participants at a recent vibration conference were asked, how many felt their efforts were recognized and appreciated by their companies, by the value produced. One individual in the group, close up 150, raised your hand! In a recent survey conducted by reliabilityweb.com, people were asked how they justified their condition monitoring programs. One responded that "we don't make money". Perhaps there is a link between “we don't make money” and the reduction of condition assessment programs! |

From here arise the questions:

- Who we are?

- Where are we going?

- do we exist?

At a time when the value of people in companies, is evaluated by its numerical contribution, in an Excel sheet of a financial, do we exist in this facet of reality?

I think that many maintenance professionals, in particular predictive maintenance, do not really exist in this essential strand of present reality. For settling for their existence in physical reality and on social media, thus become candidates for cuts in the next crisis. There, will have place, their non-existence in the organization they work for!

8 – MPM – FOR A REVIEW OF THE MAINTENANCE TASKS

The first step to clear the fog that prevents us from seeing the hidden reality and starting to discover it is to recognize that maintenance philosophies are not limited to what we are taught in schools.. There is much more than curative and preventive maintenance.

Like this, as a first step towards reaping the benefits that MPM provides, it is proposed to recognize the following maintenance tasks:

- The Psychological Maintenance

Maintenance task carried out to respond to human problems and not machine problems. Example. Tasks under the cagaço coefficient.

- The Affective Maintenance

Maintenance task performed to respond to affective issues.

- The Subjective Maintenance

Maintenance task carried out no one knows why. Examples: by the way…; it has always been like this...

9 – MPM – CONCLUSION – TOPICS TO DEVELOP

IS, therefore, This is MPM's field of action. Ignorance of this reality explains the partial failure of all the approaches used so far.. The inclusion of this reality is a necessary condition for the success of an approach that wants to be truly comprehensive..

Therefore, for the development of this methodology, we propose the future deepening of the following themes

- Parapsychology of machines and maintenance

- Unexplained phenomena and maintenance

- What the machines want is contempt

- You 6 pillars of MPM (only two know each other, the others are still buried)

- MPM and Asset Management Optimization

- MPM and quantum mechanics

- MPM is the solution

- The MPM failure curve; or inverted bidet; how MPM achieves zero breakdowns

REFERENCES

Hydrocarbon Processing 4-2002 Low technology approach to better machinery reliability