Vibration monitoring in a turbogenerator 1800 MW

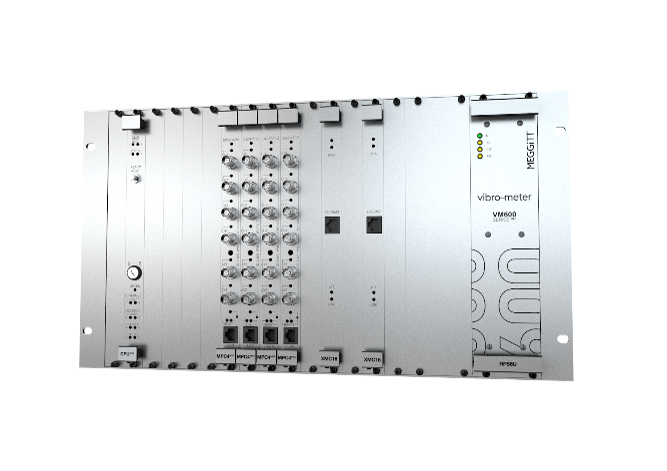

This article presents the vibration monitoring system in a turbogenerator group of 1800 MW. The monitoring system is Vibrometer brand and model is VM600.

In Portugal there are more than 20 thermal and hydropower plants where Vibrometer VM600 monitoring systems are installed.

This article belongs to a series, which constitutes the support material for the course on vibration analysis in turbomachinery. Links to the other articles can be found on here.

A Hinkley Point C nuclear power plant in the UK

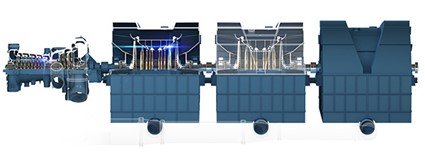

The generator set 1800 MW, model Arabelle, manufactured by General Electric, will be installed in the nuclear power plant, with steam generated in a pressurized water reactor.

Vibration monitoring in a turbogenerator – The generator set

The generator set consists of a four-stage steam turbine.; one for high and intermediate pressure and three for low pressure.

The group has a total of 10 bearings with 45 measurement points and the alternator is four pole, hydrogen cooled.

Vibration monitoring in a turbogenerator – The Vibrometer monitoring system VM600

At the heart of the monitoring system is the VIbrometer VM600 system., that provides advanced protection features and Vibration Analysis.

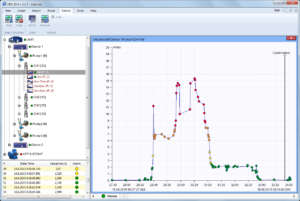

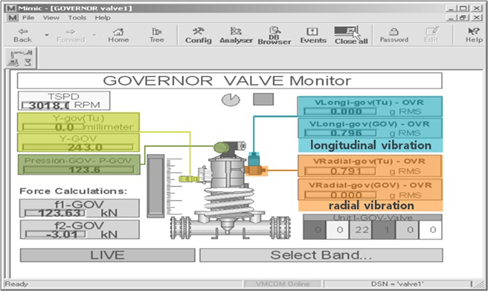

Below you can see the graphical interface of the system.

The group has 45 measuring points, with the following characteristics:

- In addition to the normal vibration sensors It also has specific sensors (pendulum, extension probe, transmitter);

- SIL2 and ATEX certification;

- shooting functionality 2 of 3 (critical axial position) e 2 of 10 (radial bearing vibration);

- IT interface with complex customer network and cybersecurity;

- Valve monitoring based on pressure measurements, bump and vibrations.

cyber security

- Need for secure remote access to data;

- Need to be able to access from the IT network;

- Need to segregate the protection function from the condition monitoring function;

- Often, using advanced technologies, such as data diodes and server replication;

- Standards such as the IEC 62443 with added importance:

- Part 4-1 Product development process compliance

- Part 4-2 product compliance

- Part 2-4 Service provider security program compliance