Vibration measurement and thermography on belts

1 – Introduction

This article presents a practical example of integrating vibration measurement and belt thermography., in inspection routines.

2 – The practical case of vibration measurement and thermography on belts

In the report of a shift of the operation of a production line, abnormal noise and high temperature was recorded on a machine. Dynamic equipment inspection was asked to ascertain what was involved.

-

The result of the measurement of vibrations

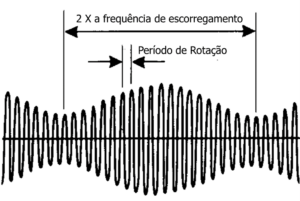

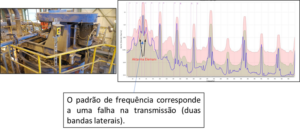

On the one hand, a Vibration Analysis through the collected frequency spectra, common vibration analyzer and data collector, did not reveal the presence of frequencies associated with the development of anomalies.

-

The result of thermography

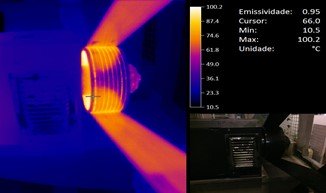

On the other hand, in the thermographic inspection carried out it was found that the motor pulley had a maximum temperature of 100 ºC.

Figure 1 - Maximum temperature recorded 100.2 ºC before intervention

In consequence, it was recommended to replace the transmission belt that, in addition to the high temperature, already showed some wear.

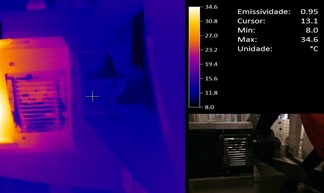

Then, in the thermographic inspection carried out after the intervention, there was a decrease in temperature in the transmission pulley, passing from 100.2 ºC for 34,6 ºC.

Figure 2 - After intervention, the maximum temperature recorded was 34,6 ºC

3 – The means of inspection

It follows from the above that the ease of diagnosis made, result of the inspection being equipped with equipment and reporting software that allow you to implement these technologies with ease.

4 – Conclusion – vibration measurement and belt thermography

In fact it is known that heat generated by slipping belts is very easy to detect with thermography. Thus, this technique is perfectly complementary to the measurement of vibrations when inspecting belt driven machines.

It follows that, when inspecting machines with belt drives and an anomaly is suspected, it is essential to perform a thermography alongside vibration measurement