Integration of predictive maintenance technologies – one perspective

Predictive maintenance and technology integration - a perspective

1 Predictive maintenance - the cost and return on investment

This article focuses on the benefits and ways of implementing predictive maintenance and technology integration.

It is currently accepted without dispute that, in many industries, predictive maintenance is essential to increase asset availability and provides the most economical way to manage industrial assets.

It is also known that in most industrial units, the highest cost of implementing a predictive maintenance system is the cost of personnel to implement it. De facto, this cost usually far exceeds the cost of investment in equipment.

In accordance with modern management philosophies, there is a strong focus on making the most of the investments made in these techniques and in particular the work of technicians who implement the inspection techniques used in predictive maintenance..

2 – Predictive maintenance and technology integration – the current situation

Currently, most of the most used techniques in predictive maintenance are mature, such as, for example, the case of vibrations, thermography, analysis of oils, etc. This means that these technologies are dominated, technicians are trained to apply them and the benefits and objectives that are easier to achieve have already been.

However, due to the constant pressure to achieve better economic results, as always, you are looking for improvement opportunities. On the other hand, it is much more difficult to implement innovative improvements than to cut costs. De facto, it takes a lot more imagination and creativity to implement improvements than to come up with a spreadsheet and cut here and there. But in fact this is the challenge that industrial asset managers face.

Now, most technicians who carry out inspections in predictive maintenance programs are strongly committed to carrying out their work in the best possible way. However, it is difficult to go further than the tools they have allow them. When more powerful tools are made available or your organizational environment is improved, inevitably this will result in the identification of more malfunctions and a greater return on investment made in the predictive maintenance system.

De facto, create the conditions that enable the identification of more failures and failure modes with the same work, is the challenge of technical managers. Without a doubt, the integration of information and predictive maintenance technologies is a way to explore.

3 – Predictive maintenance and technology integration – the definition of which should be used

3.1 – Machinery and equipment to be controlled

It is not common to include all machines in an installation in the predictive maintenance program.. Thus, as a general rule, the equipment where maintenance will be carried out according to its condition obeys the following criteria:

- The machine is critical for production;

- It is critical for quality;

- It has high maintenance costs;

- It is safety critical;

- Poor functioning of the machine has negative effects on the environment;

- It is economically viable to control the condition of the machine.

3.3 – Defining faults and failure modes to be detected

Each component of equipment can break down in one or more ways. So a machine can break down in multiple ways. Usually it is intended to detect the following types of malfunctions:

- The most common

- Those that jeopardize security

- Those with the most costly consequences in terms of costs, quality and environment

If in the case of rotating machines there are control techniques that are easy to implement, the same may not happen with other types of equipment. So the ease with which symptoms can be detected for a particular malfunction is a factor to take into account.

|

Symptom Defect |

Temperature | Pressure |

Caudal |

Vibrations |

| Imbalance |

X |

|||

| Misalignment |

X |

X |

||

| bearings |

X |

X |

||

| I desaperto |

X |

|||

| Days off |

X |

Figure - Common malfunctions in rotating machines and their symptoms

3.4 – Inspection techniques

The best measurement parameters that can be used for the purpose of controlling the condition of a machine are those whose measurement does not interfere with its operation. Among the existing inspection techniques, can refer for example to the following:

- Vibration Control

- Global level

- Bearing shocks

- Frequency spectrum

- Wear Control

- Oil analysis

- Particle detectors

- Ferrography

- Temperature Control

- Noise Control

- Leak Control

Each has advantages and defects, beyond its own limitations. Its application implies, therefore, a knowledge of all the factors at play, being common to apply more than one technique in each machine, either as a parameter to follow a trend, want to check the condition.

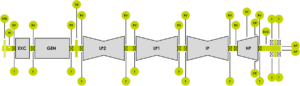

When selecting a control technique for a critical machine, It is important to note that the machines malfunctioned because one or more critical components fail.

Therefore, the most sensitive methods of inspection machine, running through fault detection in individual symptoms components, seen the greatest deviation from normal conditions to be focused on these symptoms making it easier to detect abnormalities.

The selection of a control method therefore depends on the type of components susceptible to damage and how this occurs. Possible hypotheses for controlling the degradation of these components can then be considered and it may even be possible to find a single technique that can detect all types of probable faults in a machine with reasonable efficiency..

In the case of the failure that you want to control to have a very rapid evolution, it may be necessary to set up a permanent monitoring. If this system has the ability to trigger a relay to stop the machine, then it is called, by protective. It's the call Protective Monitoring. If the purpose of monitoring is to extrapolate, from your current behavior and the recent past, your future behavior, is then called Predictive Monitoring.

On the other hand, the specific maintenance situation of each industrial unit will impose some constraints in the choice of inspection techniques and ways to implement them.

4 – Predictive maintenance – obstacles to the integration of technologies and solutions

What has just been mentioned is nothing new and presents the traditional approach used to choose predictive maintenance technologies. It is through this approach that, for example, the use of vibration measurement for controlling dynamic equipment and thermography for controlling electrical equipment, that are frequently used. Also the most frequent thing is that they have their backs to each other, almost as if they were used in watertight maintenance organizations instead of being integrated.

The new challenge is to optimize the use of these technologies.

There are two types of challenges that you have to face when you want to get the most out of predictive maintenance technologies:

Organizing:

- Compartmentalization of different groups in the organization and tightness of different sources of information;

- Motivation and qualification of people.

Technical means of predictive maintenance:

- Platform(s) Computing(s) predictive maintenance;

- Inspection equipment.

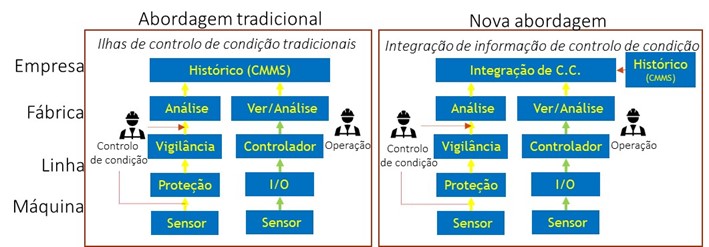

4.1 Tightness of predictive maintenance information

Currently it has become a standard for industrial organizations to have an ERP, or similar, that allows them to follow the maintenance costs in detail.

Similarly, with Maintenance Management IT platforms (CMMS), it is also intended to have a tool that allows the technical management of industrial assets to be carried out in a more or less fluid way.

However, information relevant to predictive maintenance, on the operating condition of the machines, continues to be dispersed and pulverized. De facto, it is common for this information to have no visibility ...

The search for deeper knowledge of the functioning condition of critical machinery and equipment organs is permanent. An effect of this permanent search, for more information, is the excess of information in barely readable form.

Take a concrete example of the set of completely different and independent sources of information on the state of a machine in a typical industrial installation.:

- Vibration measurement on hundreds of machines (obtained with human or automatic intervention);

- Oil analysis on dozens of machines (obtained with human intervention);

- Thermography over hundreds of electrical installations (obtained with human intervention);

- SCADAS information (automatically obtained);

- CMMS / ERP information (obtained with human intervention);

- Information for local maintenance stakeholders (obtained with human intervention);

- Lubrication information and oil analysis (obtained with human intervention).

Also take into account that the tendency is to add more systems and information and that, for many years, on existing machines, much of the most relevant information will not go through more sensors on the machines. If there is no effort to integrate information, this situation will not improve.

Hence the need for the integration of all this information that allows managers to have an intuitive and simple analysis, that at a glance gives them a view of the state of the asset and focuses on the issues where they have to invest resources to optimize the return on their investments.

This is what must be achieved with the implementation of a predictive maintenance information computer platform that makes information accessible and transparent., interested.

Informal communication channels work to a certain extent. When companies grow or there is overwork they stop working or work poorly. The need to have a single integrating information platform that condenses into an interface tailored to the capabilities of a manager, all existing information, it's obvious.

Figure - Emphasis on how to present predictive maintenance information, to improve the Optimization of Industrial Asset Management

4.2 Motivation and qualification of people

Take, for example, information on the condition of operation of dynamic equipment.

Vibration measurement inspection technicians spend their days inspecting dynamic equipment and obtaining information about its condition. On the other hand, lubrication technicians also spend their days around the same equipment, in your lubrication tasks, and have very relevant information about their operating condition.

However, it is common to work in an almost watertight manner ...

In other words, the various subsystems existing in the manufacturing environment need to have a single integrating interface, that allows, num raises, have a global view of all the information generated by the various existing systems and that draws attention to where it is necessary to invest the available resources. For those who want this interface, they should also have resources that allow them to explore the information.

In addition, it is also worth mentioning that it is common for industrial organizations not to strive to collect the information that lubricators have on the condition of the machines' operation.. De facto, it is much more common to be very concerned with reducing costs ...; it's much easier ...

too, normal practice in organizations, is that condition control technicians are, heavily loaded with work and having to work hard to comply with inspection routines, very demanding in amount of work. Is not, like this, within their reach to overcome organizational failures.

4.3 – Predictive maintenance – equipment improvement opportunities

On the other hand, however much faster equipment is used and inspection routines are optimized, technicians are faced daily with situations where they have to take breaks from their work, for reasons beyond your control. So there are inevitably dead times in inspection work, that are an opportunity for improvement.

Take for example the case of vibration measurement work, where there is suspicion of abnormal heating and where, if the thermal vision system was there, it would be used to advantage.

So it seems obvious that, for example, integrate the two technologies, is a step in optimizing inspection work, from a technical and economic point of view, with a guaranteed return on investment.

4.4 The example of vibrations and thermography as predictive maintenance techniques

Vibration analysis and thermography are condition control techniques often used for predictive maintenance. Historically, these two technologies are separated and used differently.

Vibration analysis is implemented using vibration analyzers, while thermography is implemented using infrared imaging cameras.

Thus, vibration analysis is normally used to know the condition of dynamic equipment in which the most common failure modes generate vibrations.. On the other hand, thermography is more used more to know the operating condition of electrical and refractory equipment whose most common failure modes generate abnormal heating.

However, it is also known that many mechanical anomalies generate abnormal heating and are conducive to the use, profitably, of thermography.

4.5 The trend towards the tightness of the application of these technologies

It is common for vibration analysis and thermography equipment to exist in maintenance organizations with two totally different applications..

The fact that the two techniques are totally separate also makes the bureaucratic work associated with the reports, exist in different computer applications that are not designed to seek synergies.

Vibration information also normally goes to mechanical maintenance while thermography information tends to go to electrical maintenance.

This situation is conducive to not generating synergies in the use of the two techniques.

4.6 – The combination of the two technologies on a single platform

And if the two technologies could come together on a single platform? This is possible through the integration of the image and image analysis functionality in a portable vibration device.

Besides that, integrated computer programs make it much more practical for a technician to have the necessary capacity to perform thermography and vibration analysis. In fact, many people are certified to use both. Many of the mechanical and electrical systems are best evaluated using both technologies.

4.7 The vibration analyzer with thermography chamber as a platform for integrating predictive maintenance technologies

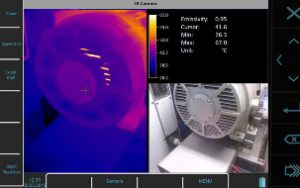

Below you can see images of equipment used as an analyzer and as a thermography camera.

|

|

| Analyzer | Photography and thermography machine |

This equipment integrates the following predictive maintenance technologies:

- Vibrations - analyzer and data collector;

- thermography;

- Analysis feed stream;

- Ultrassons;

- Camera;

- Stethoscope;

- Signal Recorder;

- On-site balancing equipment;

- Lubrication control.

In this equipment, when you want to use, the thermography chamber is connected to a USB plug on the top of the equipment, as you can see in the photos.

|

|

The thermography camera usually goes in the inspector's pocket and is assembled when he intends to use it. So it can be used optimally in inspection work.

The following image shows a bearing with abnormal heating, as presented by, in the field.

4.8 A computer application that integrates different technologies

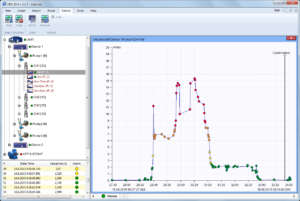

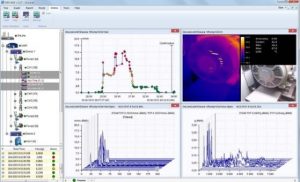

The following is an example of a computer application that integrates different technologies and that allows to generate reports of vibration inspection and thermography, automatically, easing the bureaucratic burden associated with inspection work.

5 – Conclusion

Vibration measurement, thermography, oil analysis and other predictive maintenance techniques are mature technologies. The advances and gains that can now occur, will emerge from innovative organizational solutions and equipment for integrating information and predictive maintenance technologies, such as the case of vibrations and thermography.