Identification of looseness in motor supply with MCM

The identification of looseness in the motor supply with MCM, it's at predictive maintenance it's at.

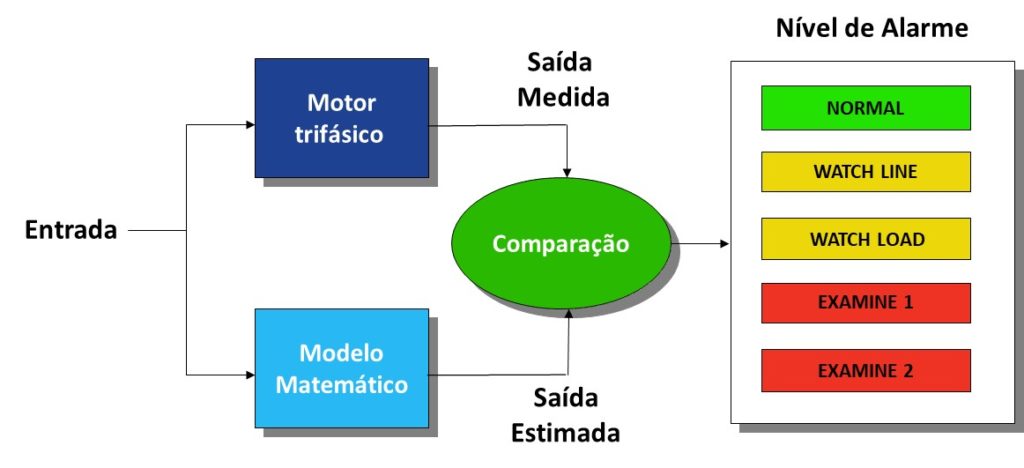

The MCM Monitoring System

MCM is a technology of analysis of electric motors recent, that works based on Artificial Intelligence that compares the real engine, to be monitored, with a mathematical model of the engine, running up to 600 different load conditions. This mathematical model is obtained from a learning period lasting a few days.

The MCM Monitoring and Diagnostic System is also designed to detect electrical failures in motors., in response to the limitations of vibration measurements with a vibration analyzer. In addition to the electrical failure modes, also detects mechanical failure modes the engine or driven machinery. This technology, like this, complements vibration analysis by detecting more failure modes of electric motors.

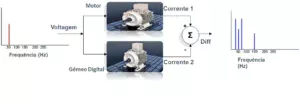

Identification of looseness in motor supply with MCM – Working principle

To perform the analysis of electric motors MCM monitor uses a combination of dynamic waveforms for voltage and current, along with learned models, to detect faults in the motor or the driven equipment. Learning is supported by an additional database, if the monitor has been installed in an already faulty engine. The monitor detects differences between the observed current characteristics and the characteristics learned and relates these differences failed.

Engine fault detection is based on an engine model, learned by the monitor, physics-based, wherein the constants in the model are calculated from data in real time and compared to values previously learned.

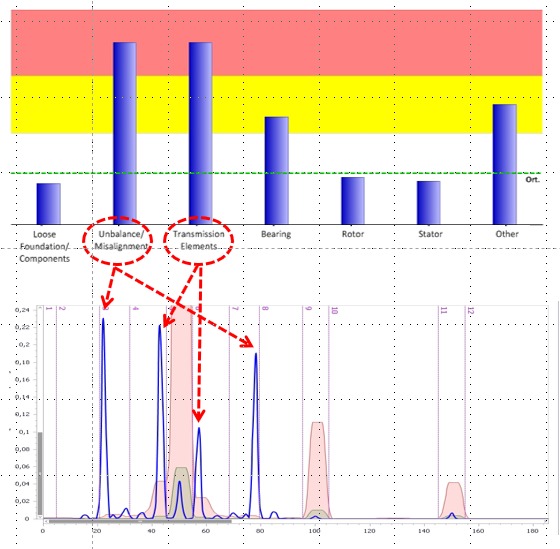

Mechanical failure detection is based on spectral power density amplitudes. (PSD) in specific frequency bands, in relation to the learned values. This information is automatically combined with specialized knowledge in diagnosis. Because of this spectral band approach, mechanical fault detection provides guidance for a class of possible failures. Sensitivity to some flaws (for example, bearing failures of the rolling elements) decrease with distance from the component fails pathways. On the other hand, failures that increase engine load are independent of distance from the engine.

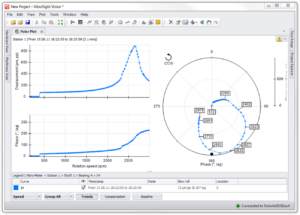

Identification of looseness in motor supply with MCM – The report

The report is issued automatically by the system, without the need for interpretation of an expert.

Practical case - identification of loosening in the motor supply with MCM

This case took place in a wrecker of a wood industry, where a loosening of a motor power circuit connection has occurred.

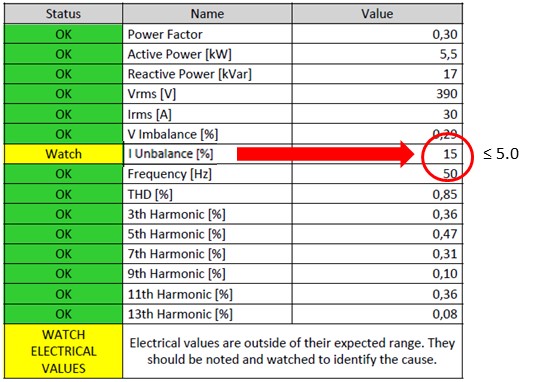

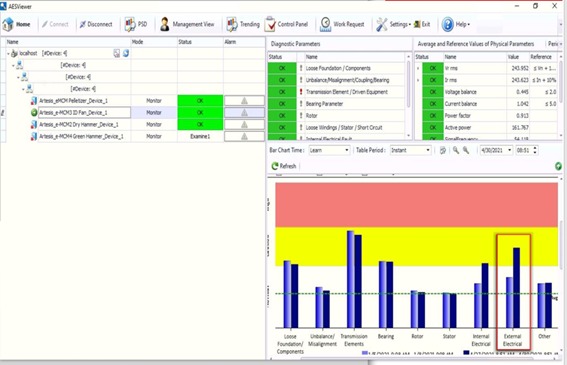

This was well identified in the diagnostic report., in which the external electrical problem was referred

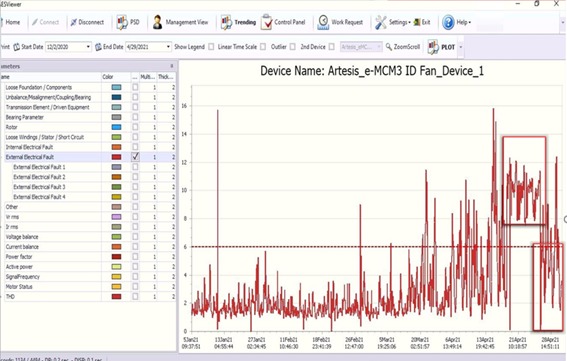

In the trend, the loosening effect was clearly visible.

When the loosening was eliminated the parameter that indicated the loosening returned to normal values.