Frequency of passing of blades

Frequency of passing of blades – Introduction

Blade pass frequency is one of the most common and easily identified vibration frequency components., present mainly in fans and bombs, but also identifiable in compressors, turbines and other similar rotating equipment.

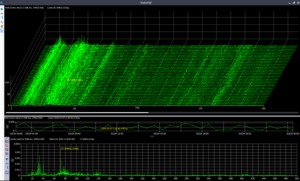

The passing frequency of blades and their harmonics are always present in the aforementioned types of machines., and usually have prominent vibration signals in the frequency spectrum.

When it takes place vibration analysis in pumps, in a vibration analyzer when performing predictive maintenance, common vibration analyzer This article presents the vibration limits in rotary-dynamic pumps as defined in the ISO series of standards..

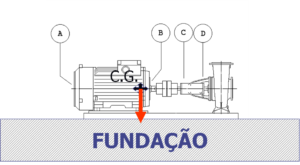

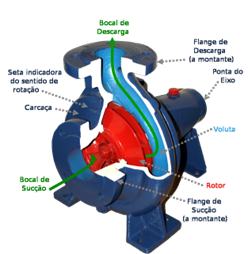

The working principle of centrifugal pumps

The liquid is directed to the central part of the rotor, enters into rotational motion and is propelled to the periphery of the rotor by the action of centrifugal force, acquiring great speed. To follow, runs along the contour of the casing where part of this velocity energy is transformed into pressure energy and is thrown out of the pump by the discharge nozzle.

The energy transferred by the centrifugal pump to the fluid is a function of the rotor diameter., drive rotation and rotor design.

From what has been mentioned, it appears that associated with each rotor blade there is a pressure wave that rotates with it..

How does the frequency of passage of blades arise

The forces that cause vibrations, are generated within the machine by pressure variations as the top of each blade passes through each of the stator volutes, causing turmoil. This is inherent in the machine design and generates vibrations..

The frequency of passing of the blades thus depends on the rotation speed of the machine and the number of blades., (picks, scrolls, pistons or lobes depending on the machine) gifts in the machine (henceforth referred to as shovels). to calculate, just multiply the rotation speed by the number of blades.

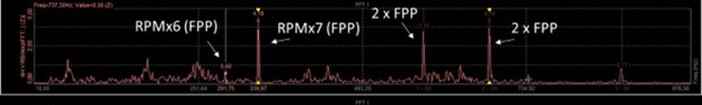

Below you can see the frequency spectrum in a pump with two impellers. One with six blades and one with seven.

Factors that influence the amplitude of the frequency of passage of blades in a pump

There are different factors influencing the amplitude of the passing frequency of blades:

- The relationship between the number of rotor blades and stator volutes;

These two numbers must be prime. Otherwise, in every moment, there will be more than one pressure wave reaching the stator volutes and the vibration level generated in the operation of the machine, will rise.

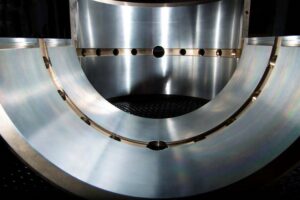

- Diametric clearance between pump impeller and stator

The smaller this gap, the greater the forces generated by the pressure waves generated in the rotor blades., not stator. For example, for pumps with a head greater than 500 meters, the minimum recommended diametric clearance is 4%.

- Geometric characteristics of the rotor/impeller

There are multiple very important geometric features to reduce the amplitude of the vibrations of the passing frequency of blades..

Other less common causes for high blade pass frequency amplitudes are rotor eccentricity or housing eccentricity., non-uniform variable height blades, improper performance parameters that can cause cavitation, lack of rigidity of impeller on shaft. Impeller stiffness, specifically, will cause sidebands at a distance of 1X, or the operating speed of rotation of the machine, that can help identify.

vibration limits

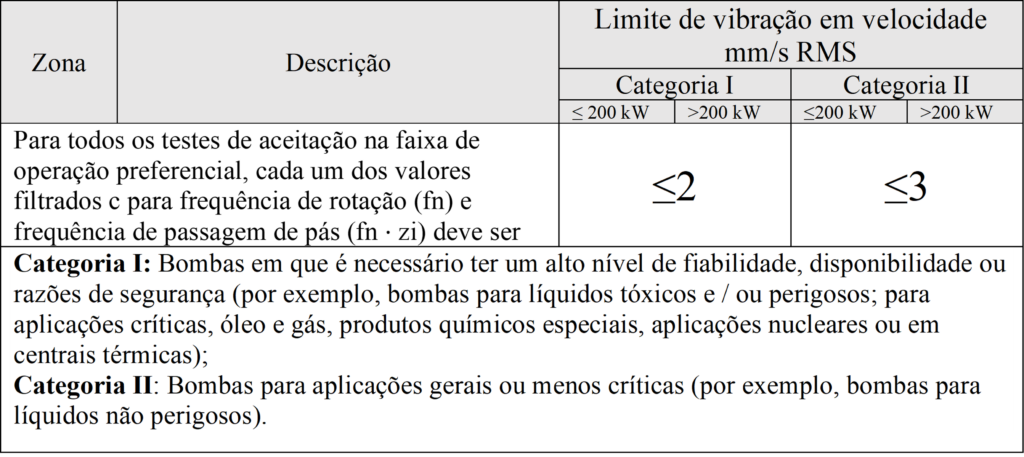

A ISO standard 10816-7 presents the limits of vibrations in roto-dynamic pumps

In this standard you can see the following table for absolute vibration limits.

Vibration limit to rotation speed and frequency of passing of blades

The variation in amplitude

If the amplitude the passing frequency of blades increases, is a sign of machine wear and is most often associated with internal problems such as impeller erosion, no case of centrifugal pumps, Flow-related issues or potential misalignment. That is, geometry variations.

Correctly diagnosing blade pass frequency and regularly monitoring their vibration amplitudes is crucial to maintaining quality in a pump application., fan or compressor. The proper blade condition and performance parameters play a key role in ensuring the process runs smoothly and is efficient..