Introduction course to Engine Condition Monitoring

This article contains links to the different articles that make up the Engine Condition Monitoring Introduction Course (MCM)

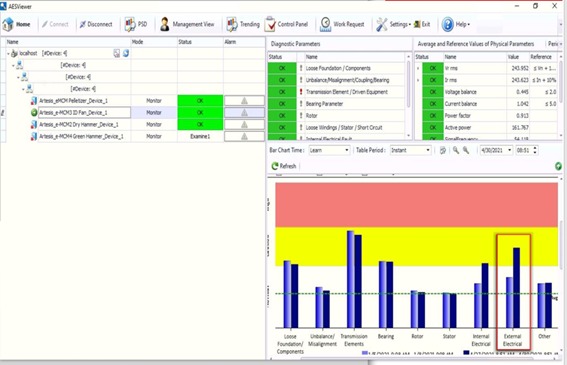

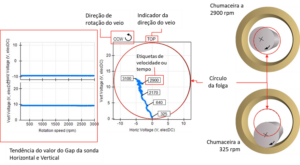

MCM is a technology of analysis of electric motors recent, that works based on artificial intelligence that compares the actual engine to be monitored, with a mathematical model of the engine, running up to 600 different load conditions. This mathematical model is obtained from a learning period lasting a few days.

This technology was developed for NASA to make the condition control of the main engine of the Space Shuttle.

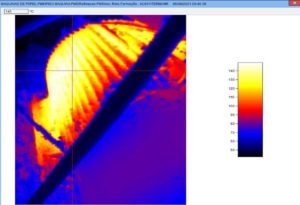

The diagnostic monitoring system MCM is also designed to detect electrical faults in engines, in response to limitations of vibration monitoring. In addition to the electrical failure modes, also detects mechanical failure modes the engine or driven machinery. Emerges as the only alternative in situations where vibration monitoring is not practical dedicated, economic or comprehensive enough. You can detect changes in the load the motor is facing due to abnormalities in the driven equipment or process, as cavitation or clogged filters and screens.

O monitor do MCM it is installed on the motor power board and thus, and requires no installation of the sensor on the engine itself, or driven machine, MCM is especially suitable for driven equipment that is inaccessible or in hazardous areas and is applicable to most types of pumps, compressors and similar machines. It is also suitable for monitoring of submersible pumps, well, downhole and encapsulated.

The ISO 20958 – electrical signature analysis of three phase induction motors

MCM Concepts

Example – Fan bearing and MCM anomaly in sensorless predictive maintenance

Example – Burnt engine and MCM in sensorless predictive maintenance

Example – A case of belts in a pharmaceutical industry machine with MCM

Example – Identification of looseness in motor supply with MCM

Example – Identification of anomaly in fan belts with MCM

Example – Identification of gear failure with MCM