Predictive maintenance technologies integration course

Here are the links to the various articles that make up the Predictive Maintenance Technologies Integration Course

Predictive maintenance - the cost and return on investment

It is currently accepted without dispute that, in many industries, predictive maintenance is essential to increase asset availability and provides the most economical way to manage industrial assets.

It is also known that in most industrial units, the highest cost of implementing a predictive maintenance system is the cost of personnel to implement it. De facto, this cost usually far exceeds the cost of investment in equipment.

In accordance with modern management philosophies, there is a strong focus on making the most of the investments made in these techniques and in particular the work of technicians who implement the inspection techniques used in predictive maintenance..

Predictive maintenance – the current status of technologies

Currently, most of the most used techniques in predictive maintenance are mature, such as, for example, the case of vibrations, thermography, analysis of oils, etc. This means that these technologies are dominated, technicians are trained to apply them and the benefits and objectives that are easier to achieve have already been.

However, due to the constant pressure to achieve better economic results, as always, you are looking for improvement opportunities. On the other hand, it is much more difficult to implement innovative improvements than to cut costs. De facto, it takes a lot more imagination and creativity to implement improvements than to come up with a spreadsheet and cut here and there. But in fact this is the challenge that industrial asset managers face.

Now, most technicians who carry out inspections in predictive maintenance programs are strongly committed to carrying out their work in the best possible way. However, it is difficult to go further than the tools they have allow them. When they become available most powerful tools or if you improve your organizational environment, inevitably this will result in the identification of more faults, and a greater return on investment made in the predictive maintenance system.

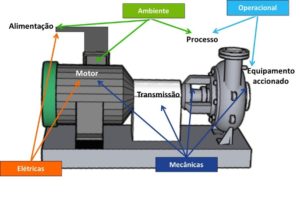

De facto, creating the conditions that allow the identification of more breakdowns and failure modes with the same work is the challenge of technical managers. Without a doubt, the integration of information and predictive maintenance technologies is a way to explore.

Connections

Example of routine integration of vibrations and thermography

Examples of integration of techniques

Analysis of oils and vibrations – integration of techniques

Thermography in vibration routines – practical example

Vibration measurement and thermography on belts

Integration of vibrations and thermography into routine

Vibration measurement and thermography - agitator review

Fault finding in bearings running at very low rotation speed, with acoustic emission