Practical case of mechanical inspection - alignment of drum drive gears

The situation

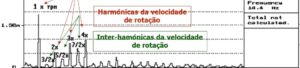

in a cooling drum, in a cooling drum measuring vibrations common vibration analyzer in a cooling drum predictive maintenance, in a cooling drum, in a cooling drum vibration analysis.

The DMC mechanical inspection service was asked to check the condition of the gear and alignment of the rack / pinion wheel teeth and alignment of the components of the pinion / rack wheel gears, coolant drive reducer couplings.

Work developed

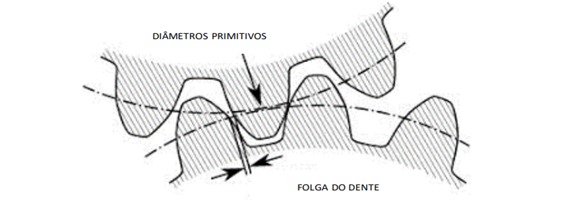

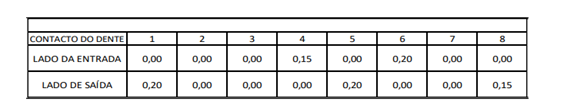

- Checking the condition of the rack and pinion teeth,

- Contact and clearance,

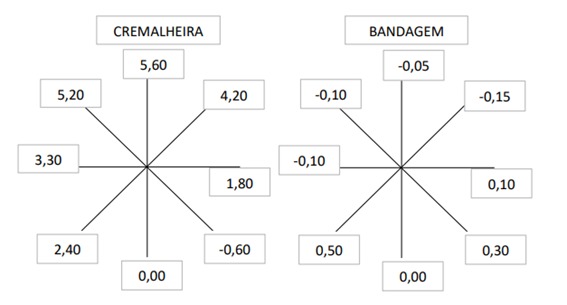

- Verification of the concentricity of the rack with the support band of the Cooler and alignment of the Reducer / Pinion.

- Correction of the alignment condition.

Checking the condition of teeth

Checking the contact and clearance of the rack-pinion teeth in 8 positions

Checking the Concentricity of the Rack Wheel with the Bandage (Cooler Support)

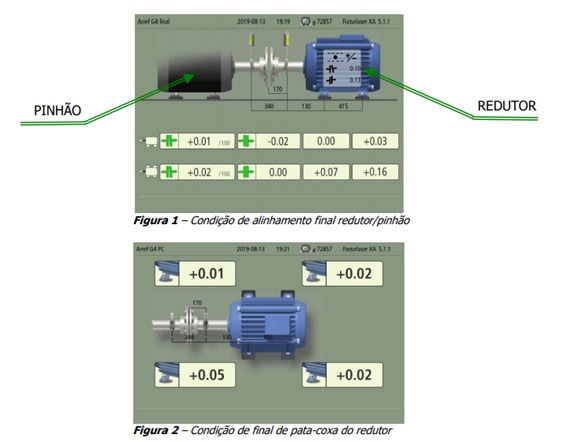

Reducer / Pinion Alignment

Completion of work

At the conclusion of the work, the alignment condition was considered good, since the deviations recorded after the corrective actions, were within the tolerance defined by the evaluation criteria adopted.

Due to the accentuated wear on the teeth, it was suggested to replace the pinion.