Motorcycle pump case study

Motorcycle pump case study

Author: Gomez Gustavo Doncel, IBERDROLA GENERACIÓN SAU

e-mail:[email protected]

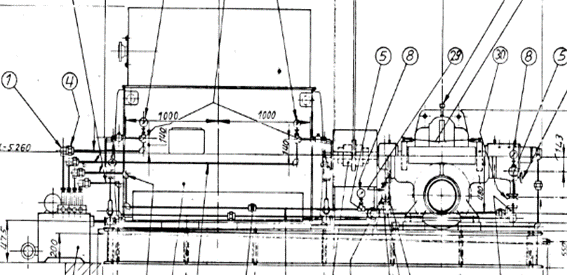

Machine features

- 2900CV electric motor (2980rpm) with hydrodynamic shoe bearings

- Direct drive with flexible coupling with double reed pack

- Closed double volute single-stage horizontal centrifugal pump (double suction, single discharge impeller), mechanical seals and radial and thrust hydrodynamic bearings in LOA ( Opposite Side Coupling).

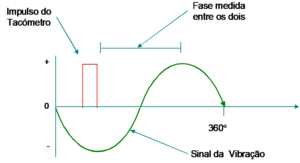

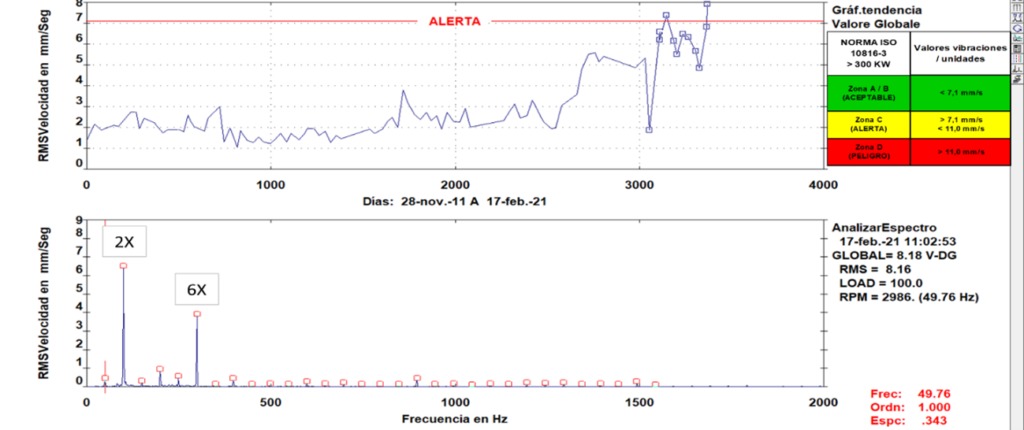

Vibrations measured with a portable vibration analyzer

Due to the power of the equipment, the reference standard is ISO-10816-3 with periodic monitoring of vibrations monthly, detecting an increase in vibrations mainly in the vertical and axial of the pump that goes into alert, Zone C of the standard, with misalignment symptoms evidenced by the 2X and 6X (pump impeller blade pitch).

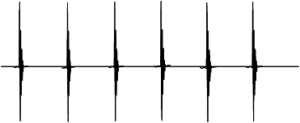

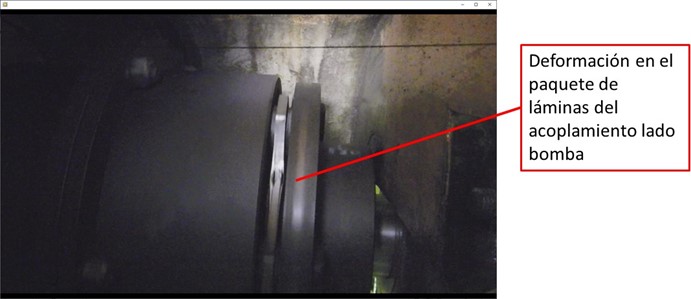

The next day vibration analysis and inspection of the coupling are carried out with a strobe lamp., finding a point zone with deformation of the coupling leaf pack on the side of the pump, demonstrating the importance and effectiveness of complementary inspection techniques in order to carry out a correct analysis.

Then, the photo of the coupling is shown 2980 rpm taken with the help of the strobe lamp.

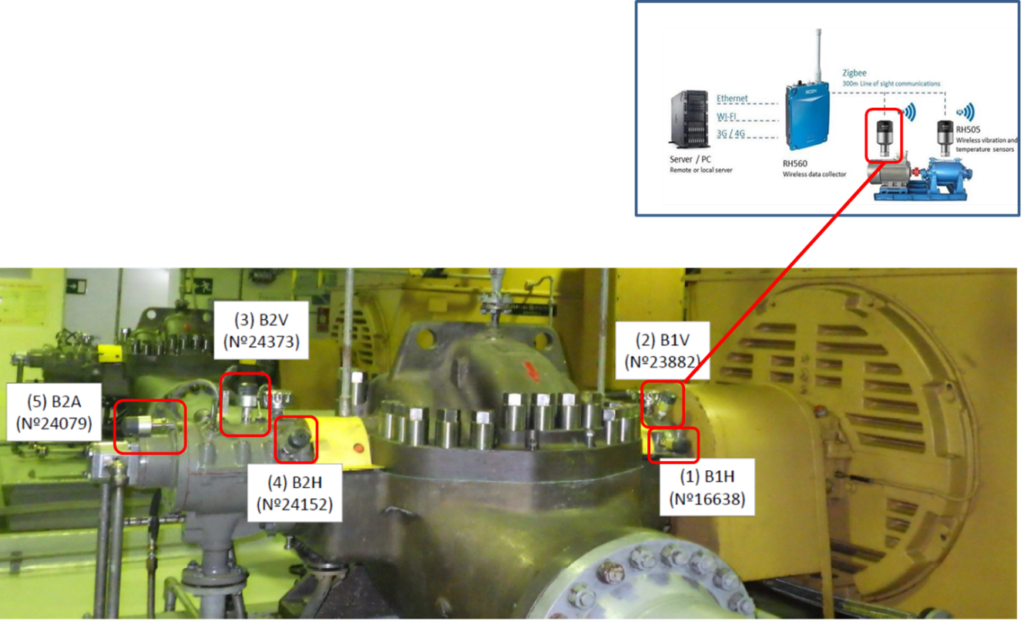

Continuous measurement with a wireless system

To be able to correctly monitor the vibrations of the equipment continuously, it is decided to install a logger with sensores Wireless of the firma Ronds, to remotely access data in real time.

What's more, periodic inspection of the coupling is carried out with a strobe lamp.

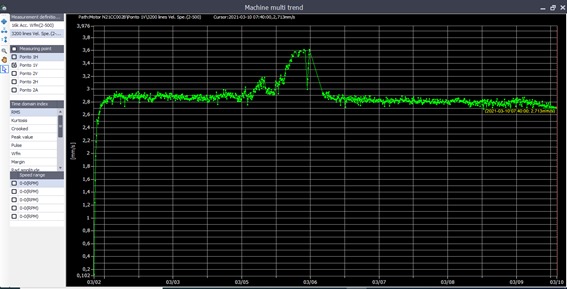

The vibrations evolve due to variations in the load of the equipment without reaching danger values (zone D), although it is decided to stop the team in a preventive way.

Actions

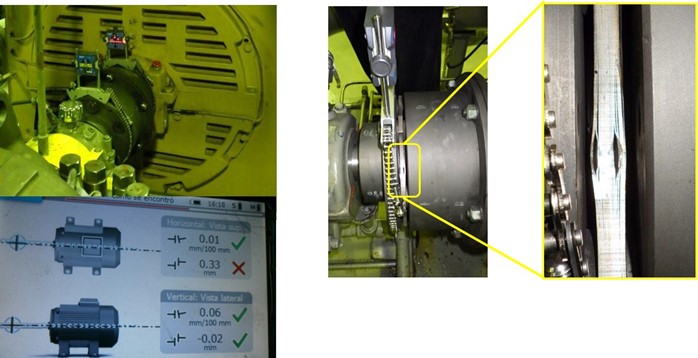

Alignment check shows horizontal requires adjustment to improve alignment. On the other hand, when examining the reed pack of the pump side coupling, deformation detected by strobe inspection can be seen.

To see a presentation on this topic click here.