Vibration Analysis ventilators

In this article, They present several case studies of Vibration Analysis in fans.

Case 1 – Vibration Analysis ventilators – malfunctions in bearings

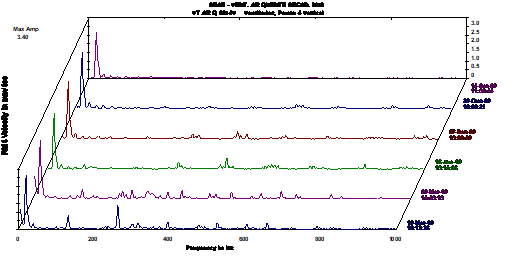

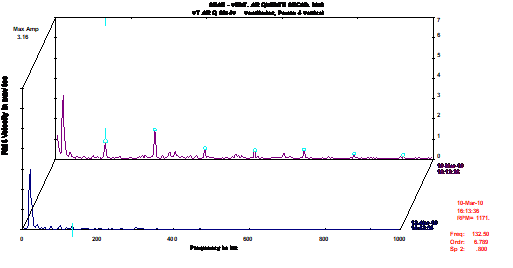

A fan comprising a motor 45 KW at a speed of 1482 rpm and the fan 1171 rpm, driven by transmission belts (identical to Figure 1), revealed that the collected data vibrométricos in the last two inspections by Vibration Analysis the fan support, side of the turbine, showed a significant change in the machine's dynamic behavior , As can be seen in the spectra shown in Figure 2.

Figure 1 – Vibration Analysis ventilators – Scheme equipment

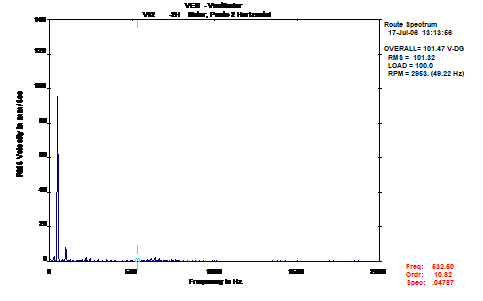

Figure 2- Vibration Analysis ventilators – frequency spectra recorded during the various inspections with a vibration analyzer

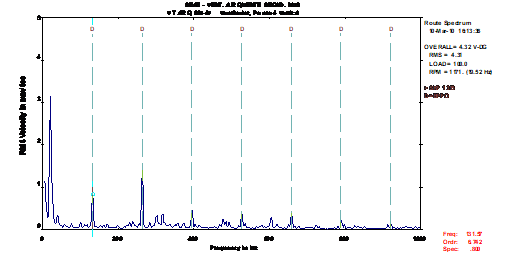

The analysis of the frequency spectra revealed that the change mentioned above was due to the presence of frequency 131,75 Hz and harmonics. According to information obtained, the bearing is installed in the fan SKF 1315. Analyzing frequencies present, It notes that the typical frequency of this bearing defect coincide with the frequencies present in the frequency spectrum (Figure 2). This leads us to conclude that the bearing side of the turbine fan is anomalies in the track of the bearing outer ring.

Note that the frequencies of the bearing only arise when we do have abnormalities in bearing components, whether the outer ring, inner ring, cage or rolling elements. These anomalies are sometimes minimal, what makes the human eye is unable to detect the. In other words, if there are no anomalies in the four bearing components, these typical frequencies will never be present in the frequency spectra.

Case 1 - recommendations made and further measurements

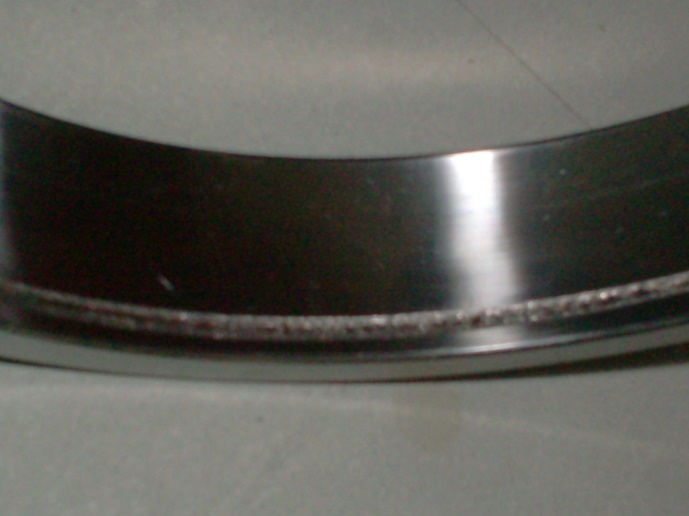

Given the severity of the abnormality, intervention was required to replace the fan bearings. After this procedure, it was found that the outer ring raceway is degraded found, As can be seen in Figure 3.

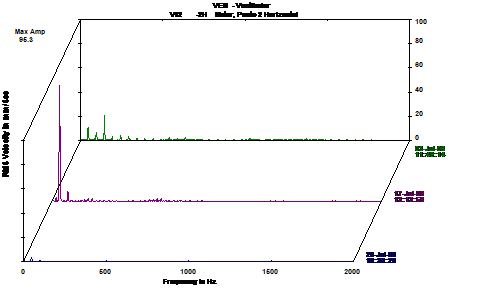

Figure 3 – Vibration Analysis ventilators – frequency spectrum registered in the turbine side of the fan

Figure 4 – Vibration Analysis ventilators – SKF bearing outer ring Lane Photography 1315

After replacement of the fan bearings, a new measurement was made where it is found that the defect frequencies previously present, They disappeared altogether, As can be seen in the spectrum shown in Figure 5.

Figure 5- Vibration Analysis ventilators – frequency spectrum registered in the turbine side of the fan, before and after the replacement of the bearings

Case 1 – Conclusion

Typical frequency bearing defect, as its name indicates, They are only present in the frequency spectrum, effectively when there is an anomaly in one of its components. The evolution of this anomaly may be faster or not, depending on a number of factors such as: lubrication, load, etc.

Case 2 - Vibration Analysis ventilators – clearances and imbalance

A fan identical to that shown in Figure 6, had high vibration values.

Figure 6 - Vibration Analysis ventilators – Scheme fan

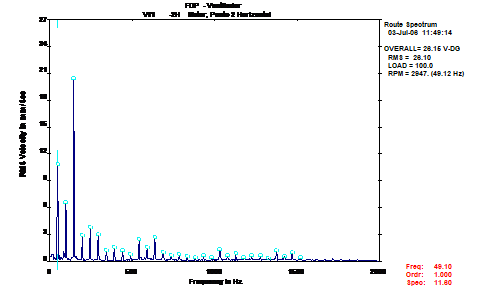

The charge balancing requested maintenance of said fan. After the first measurements, it was found that high levels vibrométricos which the equipment is submitted were found, about everything, influenced by the magnitude of the operating frequency and harmonics. this feature, illustrated in Figure 7, It was not associated with imbalance, but the gaps between a condition of mechanical components.

Figure 7 - Vibration Analysis ventilators – Spectrum collected at the drive side of the motor

The sensory inspection conducted revealed excessive clearances between the turbine hub and the shaft, as well as cracks in the fan housing, resulting from high levels of vibration to which the machine was subjected.

It was recommended to repair cracks and elimination of gaps in the hub.

After repair (encasquilhado cube), a new measurement was performed which demonstrated that the machine met with higher vibration levels, compared to the previous measurement. The performed analysis showed that high levels vibrométricos (100,8 mm/s) they were, about everything, influenced by the amplitude of the electric motor operating frequency (49,26 Hz).

This time, the frequency spectrum characteristic was associated with fan rotor unbalance (Figure 8).

Figure 8 - Vibration Analysis ventilators – frequency spectrum collected in the engine after repair

With the balancing was possible to reduce the high levels of vibration. To balance, a dough was placed 18 Grass at 0º. In the figure 9, illustrated is the improvement made after the interventions.

Figure 9 - Vibration Analysis ventilators – spectral map where the improvement is observed after the intervention (cracks, And clearances Imbalance)

Case 2 – Conclusion

By vibration analysis it was possible to identify the causes of the high levels of vibration in the machine and make the respective correction.

Case 3 - Analysis of vibrations in fans - degraded bearings

On a visit to a potential client, the head of maintenance indicated its intention to, the annual stop, receive about twelve fan motors. The idea was not to intervene in fans and benefit only the electric motors.

At the suggestion of DMC, It performed the measurement and analysis of vibration twelve fans. The inspected equipment, it was found no anomalies or malfunctions that justify intervention in electric motors.

Breakdowns diagnosed in fans were characterized by looseness, imbalances and abnormalities in the two fans bearings.

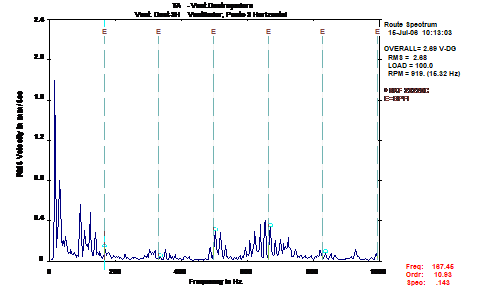

In Fans, after analyzing the collected spectra, found that the presence of frequencies associated with defects in the inner ring raceway fan rotor support bearing, side pulley (Figure 10).

Figure 10 - Vibration Analysis ventilators – Spectrum collected before the replacement bearing

Since the arrest was scheduled to brief, It was recommended the replacement of the fan bearings.

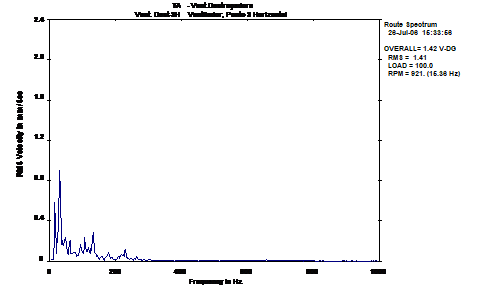

After the maintenance actions on the equipment, a new measurement was performed in order to assess the quality of intervention. In the second measurement, there was a lack of frequencies associated with anomalies in the bearings (Figure 11).

Figure 11 - Vibration Analysis ventilators – collected spectrum after replacement of the bearing

Case 3 – findings

The cost associated with providing services vibration measurement is well below the cost of upgrading the motors.

With this technique, It was able to undo the potential failure of the equipment during the production process, since initially it did not provide for intervention to replace the fan support bearings.

This technique, when properly applied, It allows maintainers identify which equipment in need of maintenance work (avoiding unplanned stops) and which, not requiring intervention, can continue to operate.