Oils and Vibration Analysis – Technical Integration

Oils Analysis and Vibrations– Integration techniques Condition Control

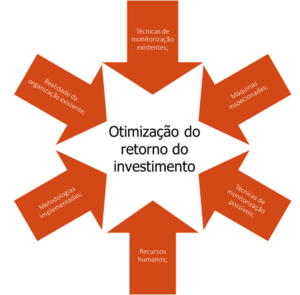

It is common knowledge that the various condition monitoring techniques, including the analysis of oils and vibration, They can be used to monitor the same defects, not being, However, common to find global perspectives of their applications, because of the natural tendency of specialists live in their "own world" and try to resolve it "your way".

Here it intended to give an overview of the integration of the two condition monitoring techniques dynamic equipment.

1 – WHY INTEGRATION TECHNOLOGIES ANALYSIS OF OILS AND VIBRATIONS

a) Machines that are not satisfactorily accompanied exclusively with vibrations

- Alternative compressors

- diesel engines

- combustion engines

- Hydraulic Piston Pumps

b) more complete information

- gears

- antifriction metal bearings

- Screw Air Compressor

- Compressors lobes ( roots)

Situations in which the analysis of oils is more clearly indicated that the vibrations

- Gears - the first signs of wear appear in the analysis of oils months before symptoms arise vibratory. In fact there are even some forms of wear gear that reduce vibration.

- large engines (approximately more than one megawatt) - better detect the wear of anti-friction metal

2 - SUMMARY TABLE OF APPLICATION TECHNIQUES

ANALYSIS OF OILS AND VIBRATIONS

Correlation data integration and lubricants and vibration (1)

| Condition | análise deLubrificantes | Analysis ofVibrations | Correlation |

| Bearings bearings lubricated oil | Strong | Strong | The lubricant analysis detects the initial fault condition. The vibrations provide more information in the later stages. |

| antifriction metal bearings lubricated oil | Strong | mista | wear particles will be generated in the oil before they occur touches or clearances. |

| Imbalance | Not applicable | Strong | The vibration detecting the unbalance. The analysis of oils possibly detect the effect of the increased load on the bearing. |

| Water in Oil | Strong | Not applicable | Water can lead to rapid failure. It is unlikely that a measuring monthly vibrations can detect this anomaly. |

| Bearings lubricated with grease | mixed | Strong | It makes sense to rely on vibrations to routine analysis of the state of bearings. Many oil analysis laboratories do not have enough experience with bearings with grease to provide reliable information. |

| Cracks in shafts | Not applicable | Strong | The vibration analysis can be very effective to detect a crack on a shaft. |

| Wear gear | Strong | Strong | The vibrations can detect which gear. The oils can determine the failure mode. |

| Alignment | Not applicable | Strong | The vibration detecting misalignment. The analysis of oils possibly detect the effect of the increased load on the bearing. |

| Lubricant condition Control | Strong | Not applicable | The lubricant can be a significant cause of failures. |

| Resonance | Not applicable | Strong | The detect resonance vibrations. The analysis of oils possibly detect the effect of the increased load on the bearing. |

| root cause analysis of faults | Strong | Strong | Best when the two approaches work together. |

3 – APPLICATION EXAMPLE DETAILED ANALYSIS COMPARISON WITH OIL AND VIBRATION

3.1 Degradation of a bearing

Monitoring with vibration analysis

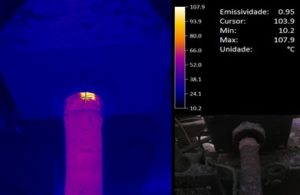

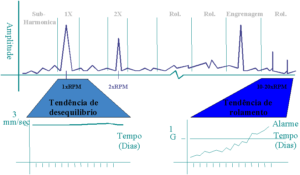

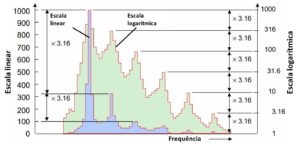

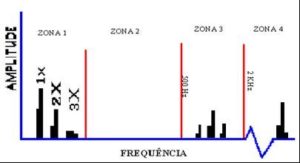

Below is illustrated as the vibration analysis is used to monitor the condition of about 80% of bearings fail due to fatigue.

1STAGE

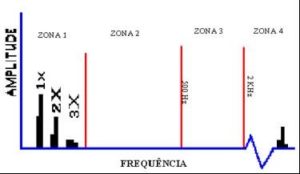

By the effect of fatigue phenomena microcracks are produced by low bearing surface. It bursts instead of vibrations at very high frequencies ( between 250 e 300 Kilohertz) which are called Acoustic Emission. Typically these vibrations are lost in the machine background noise.

Later, as wear progresses, the lower frequency range to 20 a 60 KHz. These frequencies are detected by the face detection techniques for high frequency vibrations in ( Ex: HE, HFD, Shock Pulse, PeakVue,etc.).

2STAGE

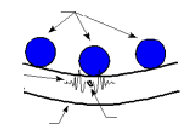

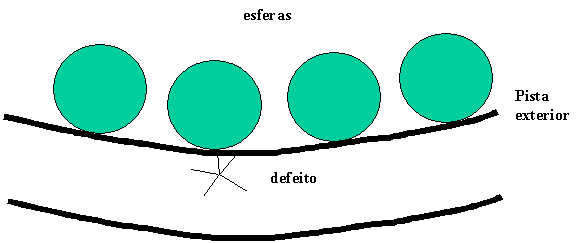

The microcracks reach the surface of the track.

The edges of the slit are sharp. They occur when the impacts they produce shock waves very abrupt. The vibrations produced are very small and less than the background vibrations produced by the machine up to a few kHz.

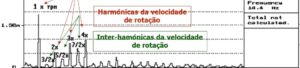

Shocks begin to excite the natural frequencies of the areas impacted, that often arise sidebands modulated by the bearing rotation speed, accelerating the spectra.

The amplitude of the vibrations at high frequencies ( zone 4) rooms.

It is time to recommend the change bearing.

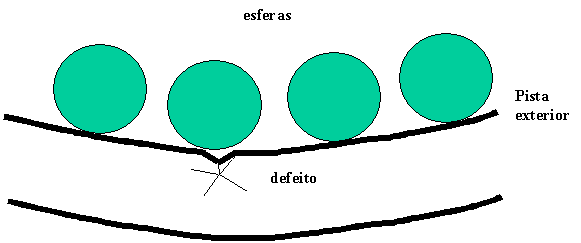

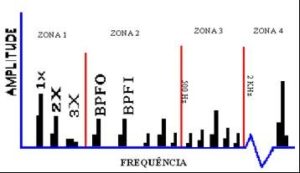

3STAGE

The slit increases and the successive impacts of the rolling bodies round their edges. The vibration amplitude increases at low frequencies.

Emerge clearly harmonic frequencies of the characteristics of bearing defects. The more advances the further degradation is content in low frequencies and number of harmonics and sidebands.

The amplitude of the vibrations at high frequencies (zone 4) continues to rise.

When you open the bearing defects are already clearly visible and it is urgent to remove the service now rolling.

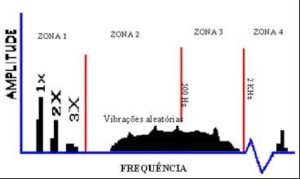

4STAGE

The degradation of the track surface becomes significant. The starting material has the effect, completely round the edges of the fissure.

In the final degradation phase component to the rotation speed (1x) may rise as a result of occurrence of the gap; these conditions arise numerous harmonics.

The degradation of the geometric characteristics of the rolling means that the frequency characteristics disappear and emerge "a mountain" in the spectrum without any frequency in the spectrum well marked. The spectrum of grass level also increases due to the shocks that occur are.

The vibratory effect can be detected in the medium frequency, and end at low frequencies (frequencies below 1 KHz).

At this stage the level of vibration in Zone 4 may decrease.

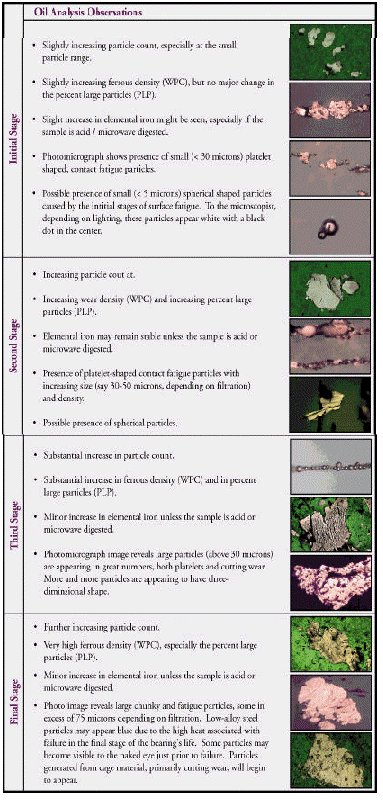

3.3 Follow up with oil analysis

| Phase | Vibrations | Oil Analysis | Comments |

|---|---|---|---|

| undamaged | Find and fix defects before they cause damage:

|

Find and fix defects before they cause damage:

|

Lanes bearings and undamaged |

| initial degradation | Detectable at high frequencies by specific techniques showing the severity

normal vibrations do not detect |

Home Wear

Initial detection of small wear particles ( > 5 m) at the beginning of abrasion, fatigue and adhesion. |

Home bites, brands and microcracks on the tracks and bearings |

| Second level | Detectable at high frequencies by specific techniques showing the severity

Vibrations can detect normal |

Detection initial bearing degradation

The particles of bearings and seals tracks are counted, steps and examined. Quantity and size of wear particles increase ( >15 m . Identify the root cause analysis using particle. |

clearly defined surface defects can cause impacts at regular intervals |

| Stage Three | Detectable at high frequencies by specific techniques

Vibrations can detect normal can be seen the characteristic frequencies |

Excellent detection of severity. Dramatic increase in the particle count of wear and particle size as the defect grows. Most large particles and agglomerate the oil ( >30 m). Evidence of secondary damage as hard particles promote abrasion. | The size defects increase due to continued tension, deformation and impact. |

| Final phase | The normal vibration indicates increasing levels, large and clearances band | Indication severe damage. The increased friction of the bearing components degraded rapidly generates wear particles. They are the oil concentrations of extreme wear particles and secondary contamination. Large concentrations of very large wear particles ( >50m) | Defects join. It can not easily where it starts one and the other ends |

4 - GENERAL RULES OF APPLICATION

As a general rule, may follow the following rules about combining the analysis of oils and vibration in detection and diagnosis of abnormalities in machines:

- It takes the two techniques to control the root cause of breakdowns.

- Often, serves as a technical fault indicator advanced in the machine while the other serves as a confirmation indicator.

- The oil analysis is , general rule, stronger in detecting anomalies in gear, hydraulic systems and reciprocating machines.

- Vibration analysis is generally stronger in detecting anomalies in the detection of anti-friction metal bearings in high-speed machines.

- Vibration analysis is often the best location of the fault point depending on the application.

- The oil analysis is often stronger in determining which wear mechanism is the failure to give.

- the two techniques to determine efficacy are needed the root cause of breakdowns.

- The correlation between the analysis of oils and vibrations is usually very good, but occur contradictory situations.

authors

- Carlos Aroeira, DMC

- Luís Blasquez, BP Portugal

5 – REFERENCES

- Maxwell, H. and B Johnson (1997) “Vibration and Lube Oil Analysis in an Integrated Predictive Maintenance Program”, Vibration Institute Proceedings; June 17-19, 1997.

- Mathew, J. and J. Stecki (1986) “Comparison of Vibration and Direct Reading Ferrographic Techniques in Application to High-Speed Gears Operating Under Steady and Varying Load Conditions”; Proceedings from the 41st Annual Meeting of the Society of Tribologists and Lubrication Engineers

- Drew D. Troyer (1998) ”Let’s Integrate Oil Analysis and Vibration Analysis” – Enteract Conference