The bridge between machine protection and condition monitoring

This article describes how the moderns permanent vibration monitoring systems Protectives bridge the gap between machine protection and condition monitoring.

This article belongs to a series, which constitutes the support material for the course on vibration analysis in turbomachinery. Links to the other articles can be found on here.

Machine protection and condition monitoring – different goals, similar instrumentation

A machine protection system (MPS) and a condition monitoring system (CMS) have different goals. Complies with American Petroleum Institute Standard for Machine Protection Systems, API Standard 670, 52nd edition (Annex N Condition Monitoring):

• The purpose of a machine protection system (SPM) is injury prevention, the prevention of damage to a machine and environmental protection.

• The purpose of a condition monitoring system (CMS) is to help maximize the availability of a machine. It does this by providing a view of the operating status of the equipment being monitored, which allows the replacement of components and/or the repair of the machine to be better foreseen, thus allowing to optimize maintenance and overhaul planning.

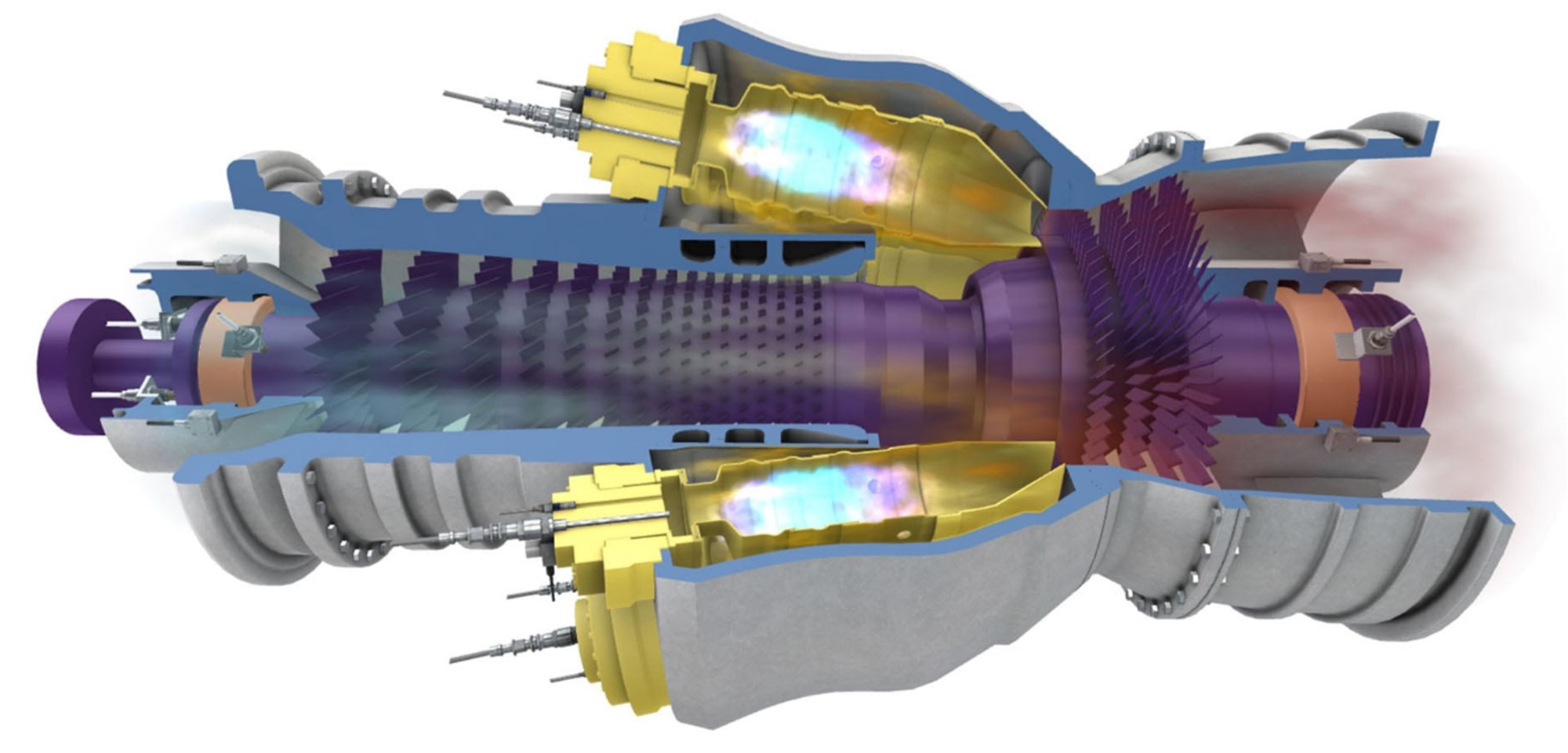

MPS and CMS systems work both, continuously monitoring machine parameters, selected. Based on years of industrial experience, a API 670 and other international standards, serve as guidance on the essential parameters for machine protection and/or the recommended parameters for monitoring the operating condition. As such, these important references, help effectively monitor the status of critical assets.

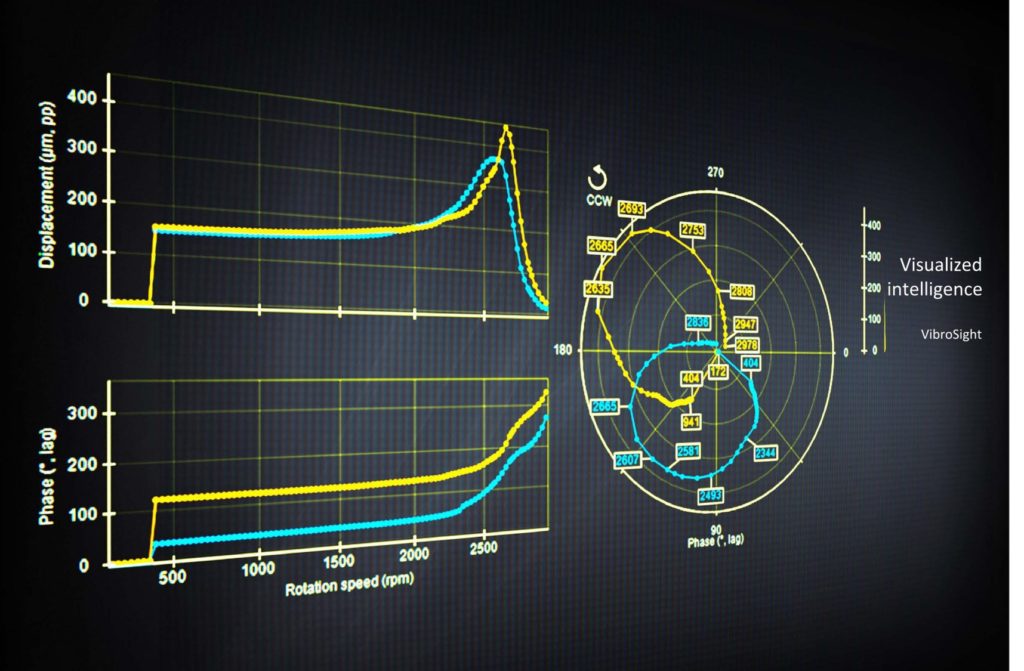

The parameters required to be monitored for machine protection and condition monitoring applications are not the same. Normally, an MPS will use some simple parameters, but reliable, such as global vibration levels which are used to set alarm levels and trigger stop logic. However, these same sensor signals carry substantially more diagnostic information that can also be used for machine health monitoring and predictive maintenance. A CMS can apply advanced signal processing techniques to extract this data., including waveforms, spectral, harmonic vibration levels (1X, 2X, etc.), shaft centerline or shaft orbits, to name just a few.

It is important to note here that CMS can be used to monitor the health of many different types of assets., and not just machines that are already instrumented with an MPS.

The perspective of the API standard 670 on the combination of machine protection systems and condition monitoring

The API standard 670, for machine protection systems, the independence and separation of systems, components or parts is an essential requirement. Before it, the standard allows the combination of machine protection and condition monitoring functionality?

The answer is a definite yes., although with the qualification outlined by the API 670 in the section 4.8 segregation:

• An MPS and a CMS can be combined as long as there are no impediments to the ability of the MPS to perform its functions, namely, the detection of alarms within the required response time and activation of the output relays, as necessary.

In practice, this means that when an MPS is combined with other systems, like a CMS or a control system, there should be no failure modes of “common cause” that might interfere with the MPS's objective of protecting the machine.

making the bridge

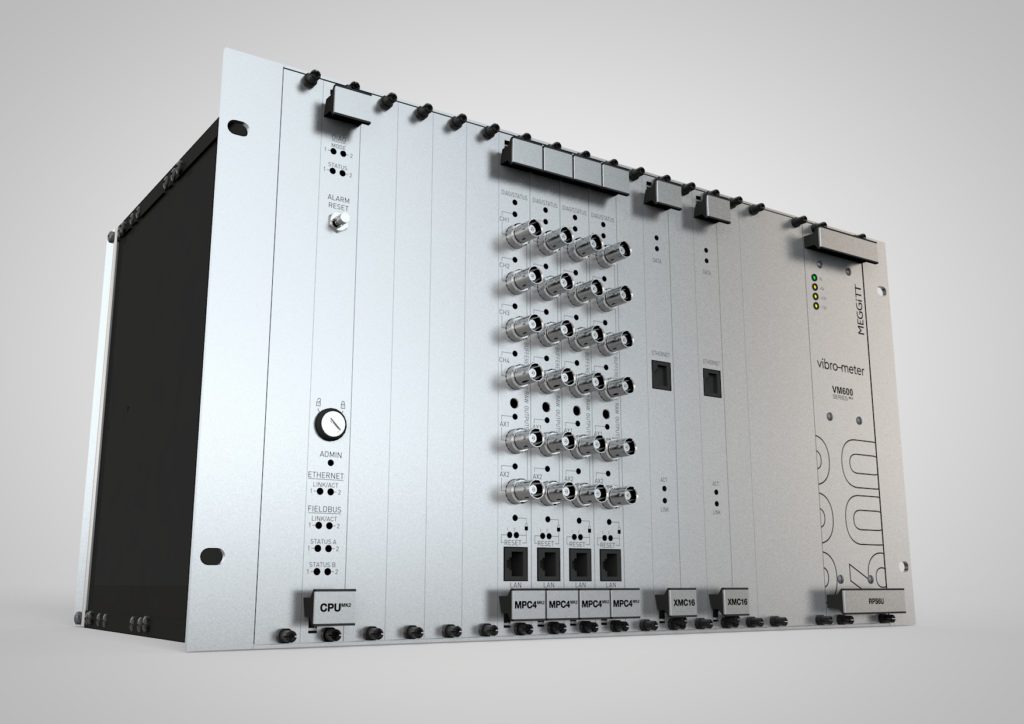

The bridge refers to the sharing of sensors/measuring chains and electronic devices, between machine protection systems and condition monitoring systems.

Although this idea is not new., traditionally, is achieved using the same sensor/measurement chain, and separate MPS and CMS devices/systems for signal processing and monitoring. Thus, electrical input signals are shared securely. Although, with this approach, digitization and separate signal processing, are largely duplicated and may be considered redundant.

over the past decades, electronic processing capabilities have dramatically improved. This provides opportunities to extend MPS processing with capabilities that used to be found only in CMS. However, the continuous flow of digital data between an MPS and a CMS must comply with API requirements 670 for system segregation.

Besides that, in the increasingly connected world, it is imperative to protect the MPS from any cyber attacks using the data stream communication path. For example, firewall technology can be implemented to securely separate both systems (MPS e CMS), while ensuring a secure and reliable data flow out of the MPS. Besides that, it is important to consider different industries, applications and equipment, which may have different requirements in terms of safety and security, and the boundary between MPS and CMS, which often results in different solution architectures.

Machine protection and condition monitoring – a combined MPS/CMS improves quality and reduces costs

A combined or integrated MPS/CMS, can significantly reduce overall system costs. Nowadays, the market components, provide a lot of computing power in a small footprint and at low prices. This allows MPS and CMS functionality., be implemented on a single device or on several smaller devices. This also translates into savings in terms of cabinet space and installation requirements.. All this helps to lower costs.

Another important consideration is the fact that separate MPS and CMS systems come with their own specific configuration software., which often doubles the setup effort in terms of time and cost (and initial training). Besides that, keeping both settings in sync with each other can be a source of problems., hard to identify.

For security reasons, an integrated MPS/CMS solution must, of course, ensure that only the MPS side can change the protection setting. At the same time, must support read-only access from the CMS side, in order to avoid unnecessary duplication, to facilitate system configuration and synchronization. for the end user, having to learn just one software/system and the ability to easily share configurations, drastically improves your experience.

Due to financial constraints, it is quite common to find essential assets (though not critical) that are protected with an MPS, but not equipped with an SCM. For this category of machines, the possibility of recording and processing signals with high frequency MPS content, directly to a parallel CMS history, would effectively allow for detailed analysis and diagnosis of a machine's health.

Looking forward

The industry's growing demand for greater availability, productivity and reliability of valuable assets is driving rapid scanning. To achieve this goal, the protection of essential and critical equipment, as well as the optimization of its operation and maintenance will become even more important. Like this, this is driving the development of better integrated machine protection solutions, smaller and more cost-effective and condition monitoring, that meet the latest security and cybersecurity requirements.