The machine holds until the next planned stop?

The machine holds until the next planned stop?

The machine holds until the next planned stop? This is the subject of this article..

DMC provides the objective answer to your question!

When a machine, critical to production, shows malfunction symptoms, a number of questions arise., to your managers:

- Does the machine, despite the symptoms of an anomaly that presents, hold on until the next planned stop?

- The failure evolution rate is slow or fast?

- I'll run the risk of keeping it running., subject to serious and costly breakdown, which will inevitably result in a longer stoppage?

- Or I'll stop it now and assume the loss of production?

These questions are commonplaces that are part of the daily lives of many asset management professionals..

The need for more information to objectively answer these questions

It is obvious that to answer these questions, in an objective way, more information is needed about the operating condition of the machines, namely:

- The symptoms presented correspond to a normal situation or an extraordinary situation;

- The symptoms shown correspond to a serious malfunction or not;

- The anomaly evolution rate is fast or slow;

- I can optimize machine operation to reduce the risk of breakdown;

- Decrease the number of starts and stops?

- Reduce load?

- change rotation speed

- Change lubrication conditions?

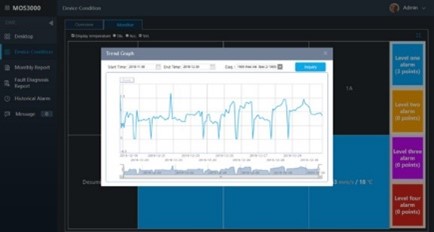

The need for smart information, accessible and permanently updated

When the answer to these questions is truly important it is also necessary that the information is permanently accessible in a user-friendly way., that is.

- There are automatically generated alarms in case of significant change in operating conditions;

- Access to information through an App.

But the system, to respond to these needs, it's not complicated and time-consuming to assemble?

No; not nowadays; assembles in a few hours. Essentially the transport time to the location.

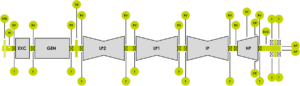

the moderns wireless systems of measuring vibrations and temperature, allow the assembly of a permanent predictive monitoring system, with advanced features of vibration analysis, overnight, in a very simple way.

| 1) Sensors are wireless, battery powered – no cables… and they are • Exia ⅡCT4 |  | Machine assembly time: 5 min |

| 2) The connection of the data collector unit to the server is via a 4G card…without cables. |  | On-site assembly time: 5 min |

| 3) The remote DMC server, already exists |  | Remote server mount time: Zero |

| 4) The configuration of measurements is done remotely before the physical installation |  | Remote parameterization time: 1 hour |

| 5) Access to the remote server is via the web |  | Time spent: Zero |

| 6) And also by App |  | Time spent: Zero |

| 7) DMC can support the interpretation of results and suggest actions |  | response time: null |

Thus, the old approach of displacing a technician with a vibration analyzer, machine, frequently.